Schedule a Call Back

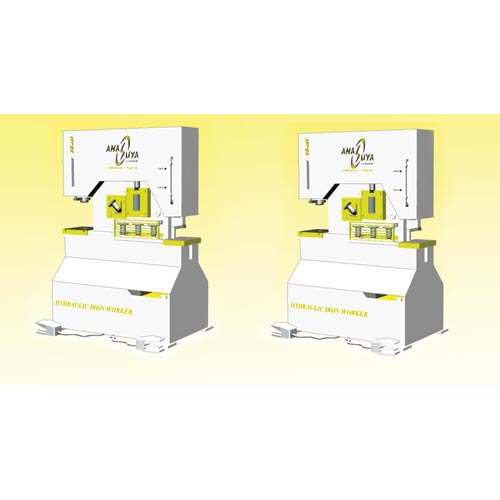

Hydraulic Iron Workers

Hydraulic Iron Workers

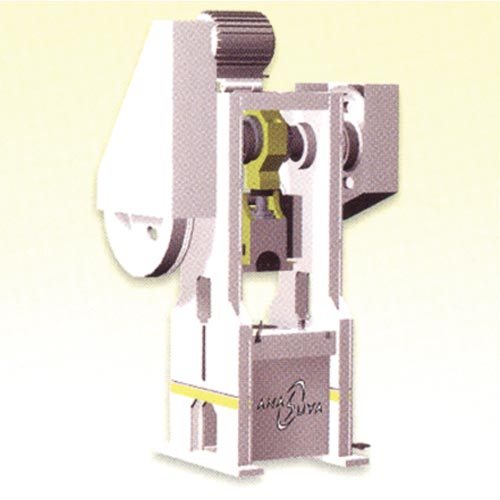

Bhagwati Engineers offers the ‘Anasuya’ range of most technically advanced Hydraulic Iron Workers, with all latest features as per international standards. These iron workers are designed and built to cut various materials with different sections in easy and efficient manner. Each machine is provided with different operation stations in order to meet wide variety of cuttings – sections like angle, channel, flat and plate can be cut very accurately and precisely. Moreover machine also has one station where differing pressing operation like punching, blanking, piercing and bending can be done.

Specialisation: Punching, flat shearing, angle shearing, bar shearing and notching.

Punching: Easily changeable punches and dies for fast tool change; thoughtfully designed stripper for visibility, safety and ease of use; standard gauging table or optional multi-stop gauging table or optional duplicating gauging table; and optional hydraulic stripper is available on double cylinder ironworkers and punching machines.

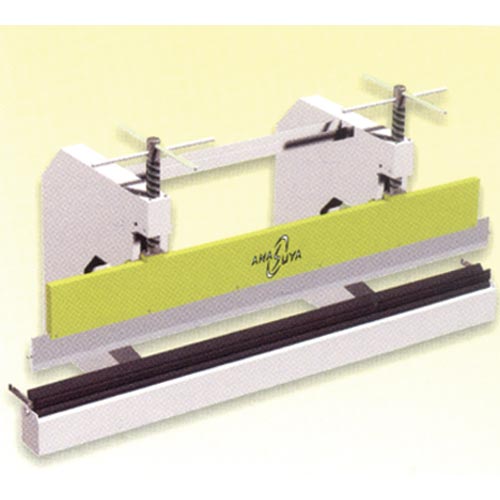

Flat shearing: Special curved upper blade to give a clean shear with minimum distortion; lower blade has four usable cutting edges; variable degree mitre-cutting on angle flange; easily adjustable hold-down; support table with guides for accurate positioning; and optional hydraulic hold-down is available on double cylinder ironworkers.

Angle shearing: Single shear with no material loss and minimal deformity; 45 degree mitre-cut is easy and clean; and featuring blades with four usable cutting edges.

Bar shearing: One hold-down for various sizes of square bar shearing and round bar shearing; and optional channel shear tooling is available for most models.

Notching: Ideal for notching on flat bars and angles; features electrically interlocked safety guard for maximum safety and visibility; gauging table with stops for precise positioning; and optional vee-notcher is also available.

Standard accessories: Main drive motor 1440 RPM; electric control panel; fine stroke adjustment rod with limit switch; manual job clamping device; blade for angle cutting, channel; cutting, flat cutting and notching; and pair of foot switch.

Optional features: Manual back gauge; blade for round bar cutting, square bar cutting, "I" section cutting; high speed system for more number of stroke/minute; and first fill of hydraulic oil.

Product & Technology News

- Low initial cost

- Low tooling cost

- Easy and quick setting

- Enormous versatility

- Accurate repetition

- User friendly

- Easy maintenance

- Standard spares, hence easy availability

Products from Bhagwati Engineer

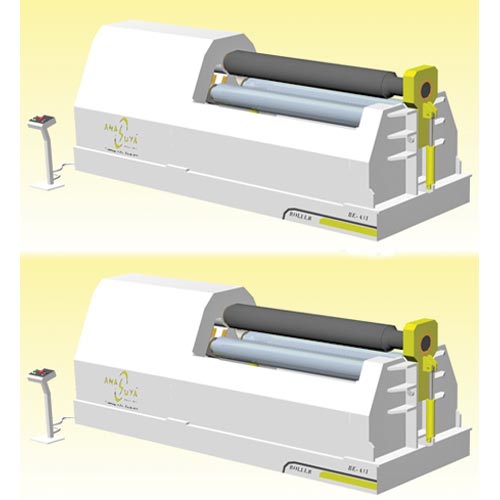

Hydraulic Plate Rolling Machine Double Pinch

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads