Schedule a Call Back

Flexible Shafts

Flexible Shafts

Suhner India Pvt Ltd has designed Flexible Shafts for various applications. A flexible shaft may be employed to transmit force or power through rotation (less likely tension or compression). It is distinguishable from wire rope in that it is not formed of braided or woven bundles of wire fibres. Instead, a Flexshaft is formed by wrapping a succession of layers of wire or strands about a mandrel, core, or central void, each layer typically wrapped in opposite direction from the last layer. As a result of this wrapped wire layer structure, a Flexshaft is uniquely adapted to transmit power in a push/pull manner, where it tends not to bunch under compression as does wire rope, and in a rotational manner where it resists forming a helix as does wire rope. Yet, and perhaps paradoxically, a Flexshaft is very flexible because of this same structure and is thus well adapted to transmit power through radical bends and other tortuous paths. Flexibleshafts have thus found many power transmission applications where the power source must be located remote from the speedometer cables, weed trimmers, and power seats in vehicles. A Flexshaft is typically housed in a sheathing or casing for a number of reasons. Typically, such a casing eliminates the potential for abrasion of the Flexshaft against structural members or components located adjacent to the Flexshaft. Additionally, the casing eliminates potential for shaft whip or harmonic or periodic deformation which would otherwise occur as the shaft rotates at high speeds. For instance, in weed trimmers, the Flexshaft is located in a plastic tube which in turn is located in the metal tube that extends from the gasoline or electric motor to the trimmer IGI head. In power seat actuation applications, the Flexshaft is also typically housed in a plastic casing not only for the reasons mentioned above, but also to reduce noise. In power seat applications, flexible shafts may be used to connect actuator motors to adjustment linkage that is adapted to move the seat forward and aft, elevate the seat front (forward lift) elevate the seat rear (rear tilt) or adjust the back of the seat (back tilt). Unlike in most sunroof applications, where the Flexshaft is employed in a push/pull manner, the Flexshaft in seat applications transmits power through rotation. For leverage, in part because of the considerable weight involved relative to the power of the motor, the Flexshaft must rotate at speeds often in excess of 3000 revolutions per minute. A Flexshaft rotating at high speeds in its casing can cause significant noise. In recent times, such noise has become more of a design factor in power seats, as vehicle interior noise levels have decreased in general due to better engineering and design. Suhner has found ways to reduce such noise considerably.

Product & Technology News

Products from Suhner India Private Limited

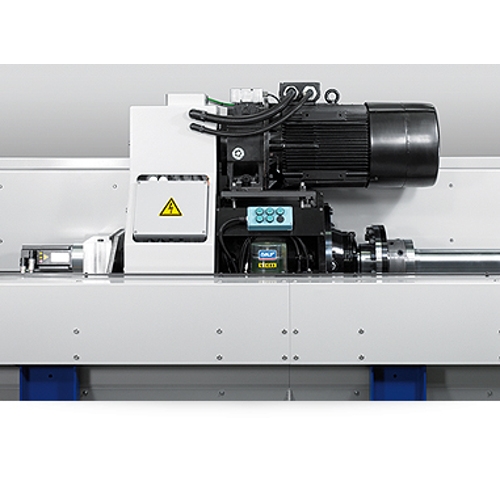

Flexible Shaft Machines – Versatile From The Outset

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads