Schedule a Call Back

Precision Drill Grinders

Precision Drill Grinders

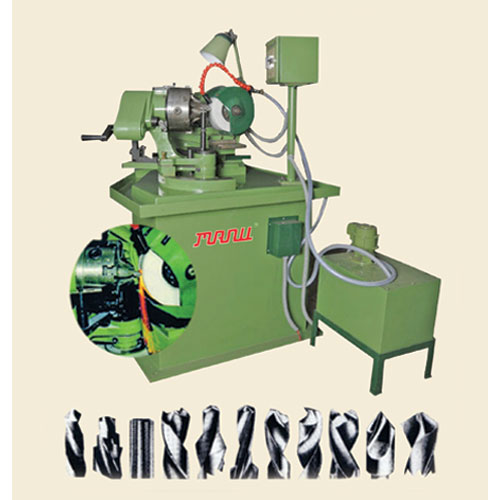

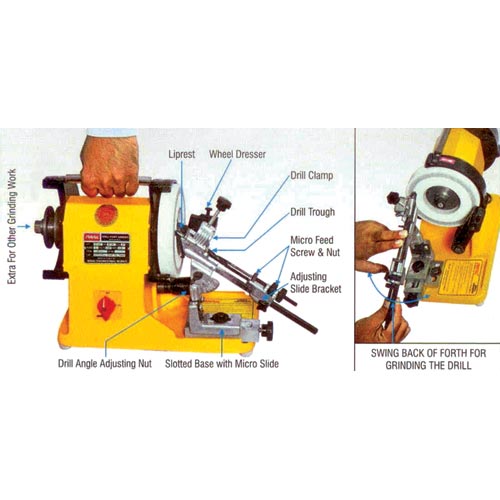

Manu Engineering Works offers heavy duty most versatile Precision Drill Grinders having capacities to grind drills of sizes 3 to 40 mm (Model DG 40) and 5 to 50 mm (DG 50). These are used for precision grinding and sharpening of all shank type cutting tools like standard drills, slot drills, core drills, counter shank drills, multi-step drills, and taps used in machine shops. They can quickly grind conventional points completely in one operation giving repeatable results. The precision 6-jaw, self-centring chuck takes drills from the prescribed sizes for respective models. The main chuck spindle incorporates frictionless linear bearings having spring loaded precision imported roller thrust bearings on both sides for smooth operation of the work head for a long period. As the drill rotates, both the lips are ground in one operation uniformly producing the correct cutting angle and precision point. The work head is fitted on a robust compound slide. The specially designed 1 HP, 3-phase, 440 V AC electric motor has three heavy-duty ball bearings with dynamically balance rotor for smooth and vibration-free grinding finish and long life. The point angle can be varied from 40° to 180° by locking swivelling work-head at the required angle. The clearance angle can be changed by adjusting the back plate of chuck by the control arm, which automatically changes the cam effect. For web thinning, a separate disc level is provided behind the standard wheel for point thinning immediately after the point grinding resulting in an accurate ground drill point. The machine is supplied with a cam suitable for RH drills. The machine lamp and coolant pump are supplied at no extra cost with the machine. Extra accessories such as special cam for 180° flat bottom drill grinding, cam for grinding pilot drill of any angle, 4 flute tap and core drill grinding cam can be supplied at extra cost, if ordered with the machine.

Drill Grinding Machines are used for precision grinding and sharpening of all shank type-cutting tools like:

- Standard Drills

- Slot Drills

- Core Drills

- Multi-step Drills

- Taps used in machine shops

- Pilot Drills

- Tap Champhering

- Countersink Drills

- 180 Flat Bottom Drills

- Closer tolerance

- Maintain repeated hole accuracy

- Compact & elegant design

- Easy & simple to operate

- No skill worker is needed

- Saves time, labour and money

Products from Manu Engineering Works

Drill Cum Hss Tool Bit Grinder

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads