Schedule a Call Back

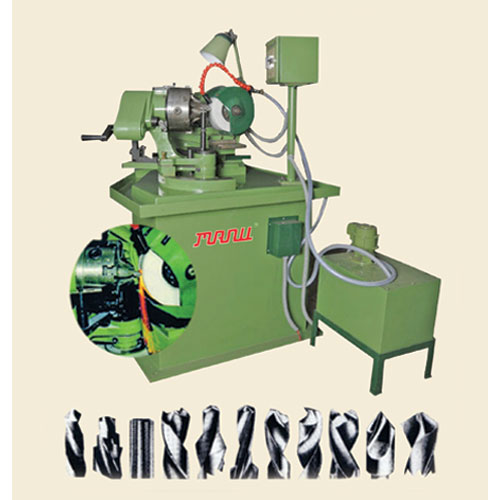

Drill Grinder

Drill Grinder

Manu Engineering Works has launched a new, bigger, import substitute, precision Drill Grinder, Model DG-80, with capacity to grind drills of size 10 to 80 mm. It is used for precision grinding and sharpening of all shank type cutting tools like standard drills, slot drills, core drills, counter shank drills, multi-step drills, and taps used in machine shops. This machine can quickly grind conventional points completely in one operation giving repeatable results. The precision 6-jaw, self-centring chuck takes drills from 10 to 80 mm sizes. The main chuck spindle incorporates frictionless linear bearings having spring loaded precision imported roller trust bearings on both sides for smooth operation of the work head for a long period. As the drill rotates, both the lips are ground in one operation uniformly producing the correct cutting angle and precision point. The work head is fitted on a robust compound slide. The specially designed 2 HP, 3-phase, 440 V AC electric motor has three heavy-duty ball bearings with dynamically balance rotor for smooth and vibration-free grinding finish and long life. The point angle can be varied from 90 degrees to 180 degrees by locking swivelling work-head at the required angle.