Schedule a Call Back

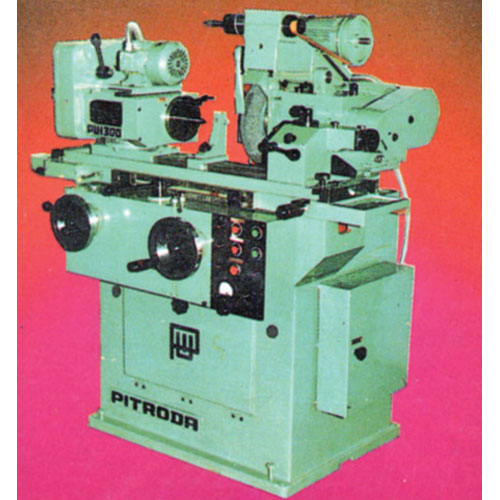

Hydraulic Cylindrical Grinder

Hydraulic Cylindrical Grinder

Pitroda Utility Industries Offers Hydraulic Cylindrical Grinder, which is a universal cylindrical grinder hydraulically reverse forward operated. This grinder is available in various models like pui-300, pui-450, pui-500, pui-600, pui-800, pui-1000, pui-1250 and pui-1500.

Base: The base is made of close-grained cast-iron and is well ribbed. The robust design of the body minimizes vibration and distortion. The guide ways one side flat and the other 'V' type are precision hand scraped to match the corresponding surfaces of the table slides.

Wheel Head: Sturdy design to ensure maximum rigidity and smooth operations. Spindle made of nickel chrome steel is duly hardened, ground, and lapped. The spindle runs in "Phosphorous Bronze Metal" Adjustable taper bush bearings in oil bath. Imported double acting thrust ball bearing takes the spindle thrust load, which is adjustable. Automatic lubrication is by oil splash lubrication systems. Drive is by means of "v" belts.

Work Head: The work head is built for grinding operation both with stationary and revolving center work head spindle runs in oil body and fitted with 'Super Quality' imported taper roller bearings or (at extra cost) adjustable gunmetal bush bearings. The drive to the Work Head spindle is by "V" belts.

Table: The table is composed of two parts (a) plain table (Bottom Part) provided with a "V" and flat guides resting on bed ways and (b) a swivel table (upper part) which can be swiveled easily and rapidly by means of a fine adjustment screw on the right hand side of the table. Angular setting is effected with a scale Longitudinal hand travel of the table is by rack and pinion arrangement and automatic travel is mechanically operated with a separate electric motor.

Tail Stock: The adjustable spring-loaded Quill travels in truly bored reamed and honed tailstock. The tailstock travels smoothly all along the length of table right up to the work head.

Internal Grinding Attachment: The hine type internal grinding attachment is conveniently located on the wheel head and is driven with independent electric motor through a flat endless belt giving the highest efficiency. The spindle of the internal attachment is suitable for grinding cylindrical & tapered holes.

Coolant: A generous coolant supply is provided with an electric coolant pump fitted on coolant tank separately provide.

Electricals: The machine is supplied with electricals suitable for the supply of 400/440 v ac 50 cycles, 3 phase, electric motors are of reputed make. The machine has push bottom switches, contractors and amp meter.

Standard Equipment: Electric motors, electric panel box, belts, coolant pump fitted on tank, grinding wheel, grinding wheel flange attached with the machine and dressing attachment (without diamond) dead centre two.

Optional Accessories: Internal grinding attachment, internal spindle, swivel of wheel head, three point steady rest, two point steady rest, additional wheel flange, true chuck flange, revolving center NT-3 & MT-4 wheel balancing arbor, wheel balancing stand, radius dressing attachment, angular dressing attachment.

Products from Pitroda Utility Industries

Precision High Speed Internal Grinding Spindles

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads