Schedule a Call Back

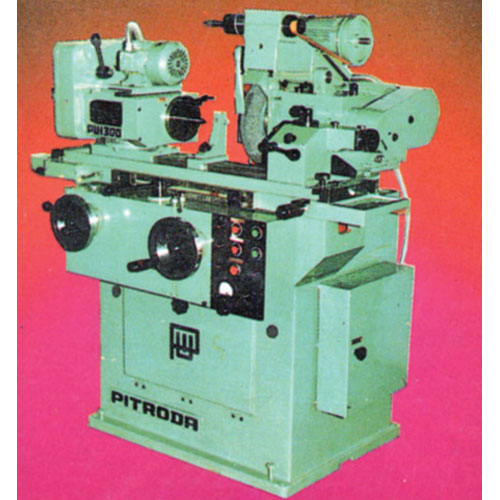

Centreless Grinding Machine

Centreless Grinding Machine

Pitroda Utility Industries offers a Centreless Grinding Machine having precise and rugged design. These machines are known for high accuracy, economical operation and reliability of performance for through feed as well as plunge grinding operations of various metallic/non-metallic cylindrical parts, e.g., plain taper, shouldered, special, form of multi-diameters. The machines are suitable for both large and small production jobs. Applications are mainly in manufacturing of bearings, automobiles, die-punches, oil engine parts, long bright bars surgical instruments, bolts, studs, drills, and various machine tools parts.

Bed:

The bed is made from close grained cast-iron, adequately ribbed with box structure design.

Grinding Wheel Head:

The grinding wheel head is of sturdy design to ensure maximum rigidity and smooth operation. The spindle is made of nickel chrome steel, duly hardened, ground, and lapped. The spindle runs in phosphorous bronze metal adjustable taper bush bearings in oil bath. Automatic lubrication is obtained by imported double acting thrust ball bearing that is adiustable and by oil splash lubrication systems. The drive is by means of "V" belts. .

Regulating Wheel Head:

The regulating wheel head is mounted on feed slide and fed by hand wheel as well as plunge lever. The spindle is made of nickel-chrome steel, in hardened and ground. This spindle is mounted on precision taper roller bearings and runs in oil bath. The spindle is driven through worm and phosphorous bronze worm gear. It is available in different speeds to suit various job diameters.

Work Rest:

The work rest is mounted on the bottom slide and it carries work blade fitted on it. The work blade can be adjusted up and down to suit various works and it can support the work while being ground.

Standard Equipments:

Electric motors, electric control panel box, coolant tank with pump, grinding & regulating wheels with its flanges, standard work rest blade (simple), dressing attachments fitted with two diamond dressers, set of Allen keys, of fix spanner, oil can, grinding wheel flange puller, standard parts list and grinding wheel spindle bush bearing setting manual.

Optional Accessories:

Work rest blade in 7 different sizes for job diameter 2-4, 4-8, 8-15, 15-25, 25-40, 40-60, 60-85mm; extra heavy duty work rest base to grind job more than medium size; special work rest blade for job diameter below 2mm; additional grinding wheel flange; additional regulating wheel flange; grinding wheel balancing arbor; grinding wheel balancing stand; profile dressing attachment; magnetic coolant filter equipment; bar feeding attachment; micro-feed system for fine feeding; semi automatic taper roller through feeding attachment as per taper roller sizes; control wheel head spindle with bush bearing same as grinding wheel head spindle; machine lamp; hydraulic dressing devices for both the wheels.

- Facility to swivel complete control wheel side unit (which comprises of control wheel, head, steady rest and feeding unit) about vertical axis 5 degrees, in either direction

- The idea is obtained from imported centreless grinder

- This device proves quite economic production for it has three main advantages - quickly obtainable accurate parallelism between the grinding wheel and control wheel axis, grinding wheel wearing is avoided while job taper setting since there is no dressing needed at all and for tapered job up to 5 degree, no need to dress wheel in taper

Products from Pitroda Utility Industries

Precision High Speed Internal Grinding Spindles

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads