Schedule a Call Back

All-Direct Drive Cnc Gear Shaper

All-Direct Drive Cnc Gear Shaper

The FS180 Mark III CNC Hydrostroke gear shaper utilizes six servo-driven axes of motion for higher speed cutting cycles in such application as smaller gears (typical of those used in automotive transmissions) and other shaped components. The gear shaper employs the company's patented technology for hydraulic stroking with accelerated return strokes. It is said to improve the quality of the cut and extend cutter life through smooth, controlled cutting force applied with CNC adaptive control. Its six servo axes are stroking speed, elevation, work spindle rotation, cutter spindle rotation, infeed speed and position, and cutter spindle backoff. A GE Fanuc 15 MB computer control provides high-speed processing to support speeds as fast as 2,000 strokes per minute. A high-volume production application with automated part handling will demonstrate these capabilities. The loader on display features a design that requires minimal tooling changes within its capacity range. The machine handles gears with pitch diameters up to 7"(180 mm) and face widths to 1-1/4"(32 mm). In addition, a wide range of non-gear components and contour shapes such as cam lobes can be produced with this type of machine. Quick-change tooling, automation packages, and turnkey process engineering are available as options.

Product & Technology News

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

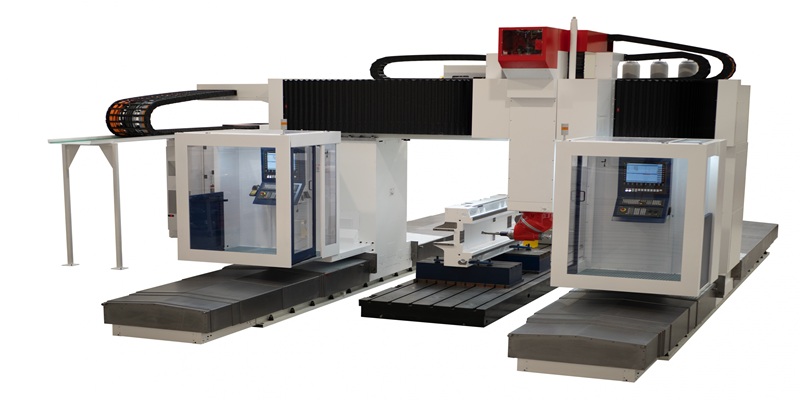

Versatile Machining Capability Through Ram Type Milling & Grinding Heads