Schedule a Call Back

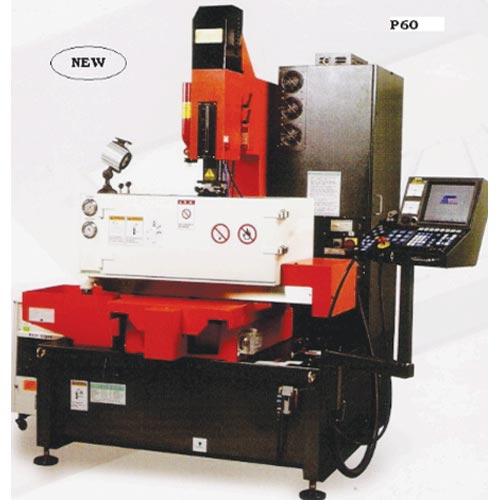

CNC EDM

CNC EDM

Mitsubishi Electric, Japan, is the world leader in manufacture of CNC EDM. Mitsubishi CNC EDMs are known for simple operation, space saving design and outstanding machining performance. The EX Series Mitsubishi CNC EDM machines are compact in design. The ease of operation is due to table fixed type and column and hence job setting is much easier. Dielectric fluid temperature control device is provided as standard and this is a refrigerated cooling system. MF adaptor is provided as standard. With the help of adaptor abnormal wear of electrode during biting and stepped machining is prevented. The new fine pulse power supply dramatically reduces the finishing time. It also minimizes excessive wear and poor surface finish due to machining waste like sludge. The fuzzy PRO 2 controller makes complex machining task very easy. Automatic recognition of machining surfaces results in optimal machining conditions. New programming method (ESPER) is introduced recently by Mitsubishi. With the help of this function multicavity machining is possible. It reduces the machining time by allowing 3 dimensional side servo machining. User friendly set up function like axis rotation function, fully supported C axis function, automatic electrode measurement, automatic workpiece measurement, multiple work coordinates and dry run function are provided in the machine. The orbit function includes a variety of orbit patterns like hexagon, semicylindrical, semi-spherical, rectangular, round, 3-D radiation, 3-D circle, C axis linked orbital rotation and orbit compensation function. The servo method used is intelligent AC servo. The drive method is direct drive and not belt drive. The Mitsubishi control system is 32 bit close loop system. 14"colour CRT and graphics is provided as standard. Self diagnostic function is provided on the machine. Mitsubishi CNC EDMs are known for high metal removal rate, low electrode wear and good surface finish. In EX Series super fine finishing circuit, mirror finish circuit, super low wear circuit are provided as standard. Automatic tool changer can be offered optionally.

Product & Technology News

Products from Sanki Machine Tools (India) Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads