Schedule a Call Back

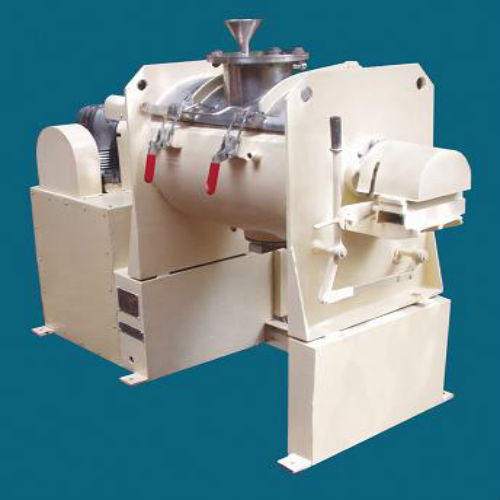

Twin Arm Mixer cum Kneader

Twin Arm Mixer cum Kneader

Traxit Engineers offers a Twin Arm Mixer cum Kneader (Sigma Mixer) is also called universal mixer, as it can be used for mixing of products in various phases, i.e., free flowing solids, liquids, light pastes, heavy pastes and dough. The ideal use is however for the last two applications. The equipment basically consists of a horizontal trough having “W†cross-section formed by joining of two opposing “Js†at their shorter arm. Each “J†houses a mixing element or arm supported by antifriction bearings mounted on heavy-duty side plates on either end of the trough. Both the arms contra rotate towards each other generally at different speeds. The mixing action is a combination of bulk movement, smearing, stretching, folding, dividing and recombining as the product being processed is squeezed between the mixing arms and side walls; mixing arms and the centre saddle and between the two mixing arms. The equipment can be supplied with different materials of construction for contact parts like carbon steel, wear resistant steel, stainless steels to AISI-304 or AISI –316, aluminium, hastelloy, etc. The container can be designed for operating under positive pressure or under vacuum and can be provided with jacket for heating or cooling the products being processed. With proper selection of features, this mixer cum kneader can be used as an effective dryer or reactor. It can be supplied from laboratory models having brim capacity of 3 ltr to production models of 2500 ltr. Sizes bigger than the above can also be designed and fabricated to clients’ exacting requirements. Applications: for processing viscous to highly viscous products mixing alone or mixing combined with kneading, grinding, dispersion, shredding, drying, etc. The picture depicts a 2000 ltr equipment with a 75 HP drive and 5 HP hydraulic tilting arrangement. The specialty of this particular model is that in-spite of having hydraulic tilting the overall height has been maintained to minimum possible. This is a useful feature where headroom is limited and it also facilitates in loading and discharging of raw material. Mechanically, the lower level of the container gives more stability to the equipment.

Products from Traxit Engineers Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads