Schedule a Call Back

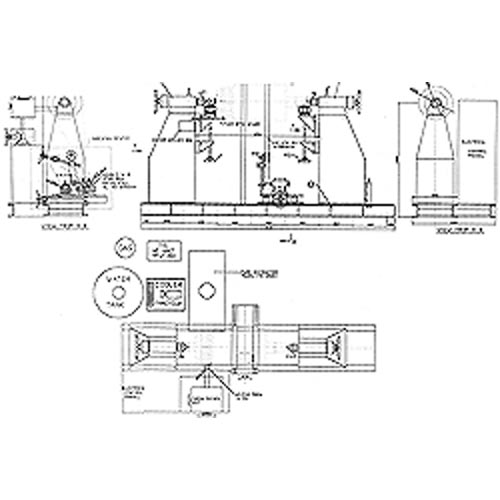

Dynamic Commutator Seasoning Plant

Dynamic Commutator Seasoning Plant

Vikrant Special Machines Private Limited offers Dynamic Commutator Seasoning Plant. Commutators of Traction motors are rotated at 3000 rpm and heated to a temperature of 220 degree Celsius for a period of 40 hours in 4 cycles or as specified to simulate the actual operating condition of such motors. After every cycle the commutator is pressed before subjecting it to the next spinning cycle. The commutator is mounted on shaft, which is supported on two heavy-duty robust construction split type-bearing housing. The bearing housings are force water cooled by means of a large capacity two tier water tank equipped with a motor and pump of adequate rating. The two bearing housings are mounted on rigid fabricated bases capable of absorbing all vibration. Both the bases on the either side of the shaft and the Oven is mounted on a heavy duty fabricated common base frame which has provision for secure grouting on the shop floor. The drive to the shaft is provided from a 3000-rpm AC motor through pulley and belt arrangement. Provision for easy tensioning of belt is provided. The commutator is unloaded with the shaft by dismantling the split bearing housings. A circular oven is provided with 24 KW mineral filled tubular heating elements, which are, mounted on the lower half of the oven with connection at one side. The heaters are protected with SS perforated sheet. The top half of the oven is in two parts and is hinged, so that the commutator can be loaded and unloaded with ease. The top half of the oven is also fitted with a SS reflector to ensure even distribution of the heat inside the oven. The AC motor is controlled through an AC VVF drive and the rpm increase is gradual. The seasoning cycle is controlled through a Timer and Temperature controller with feature of auto shut down of plant after completion of one cycle. In case the customer so requires a Temperature recorder can also be provided for maintaining record of individual commutators. All necessary safety interlocks are in built such that in case of motor tripping, the heaters will be switched off automatically to prevent damage to the commutator. The company also offers Gang Drilling Machine, Edge Rounding Machine, Weld Positioners, Hydraulic Scissor Lift Platforms/Tables, Automatic Coil Winding Machine, etc.

Products from Vikrant Special Machines Private Limited

Tangential Type Threading Machine

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads