Schedule a Call Back

Pneumatic Piston Vibrators

Pneumatic Piston Vibrators

Pneumatic Piston Vibrators are effective in solving bulk material flow problems by incorporating the most advanced manufacturing techniques, quality control, and bulk solids flow technology. Bridging of material occurs when the cohesive strength of the bulk material is sufficient to form a bridge of material capable of supporting the column of material above it. Ratholing occurs when the sliding friction between the material and the vessel wall slows the flow of material in the outer perimeter of the vessel. The innermost material is able to flow through the central flow channel, and the outer material is restricted. Vibration, when applied properly, reduces the cohesive strength of the bulk materials and reduces sliding friction, thus eliminating the two major bulk material flow problems.

Product & Technology News

- Linear vibration - The forces generated by pneumatic piston vibrators are linear, so they may be directed and concentrated in the problem area. In addition, no damaging shear forces are applied to the mounting bracket or storage vessel.

- High amplitude, low frequency - The high-energy impulse vibration generated by pneumatic piston vibrators is effective in reducing the strength of bulk materials and the sliding friction between the material and the bin wall. This is accomplished without approaching potentially damaging resonant frequencies.

- Low maintenance – When installed and operated properly, pneumatic piston vibrators provide years of effective performance.

- Tapped exhaust - For dusty, corrosive, underwater, or sanitary applications, tapped exhaust ports are available to protect the vibrator or to remove the exhaust from an area.

- Internal spring – When a vibrator is operated with the piston in a horizontal orientation, a spring is recommended for instantaneous starting.

- Internal teflon coating – Teflon coating is recommended for highly corrosive or abrasive atmospheres.

- Filter, regulator, lubricator – Pneumatic piston vibrators require a clean, dry, lubricated air supply to provide the optimum operation and service life.

- Solenoid valve – Vibration is most effective when it is intermittent and when it is applied only when required. Solenoid valves control the vibrators electrically, and allow integration into the existing process.

- Manual valve – Flexible hose assemblies with close fitting N.P.T. fittings should be used to make the direct connection to the vibrator.

- Electronic timer – Timers may be integrated into the vibrator control logic to allow intermittent vibration when the process requires it.

- Pneumatic timer – In applications where electricity is not available or allowable, a pneumatic timer may be used to provide intermittent operation.

- Exhaust protector – In corrosive or abrasive atmospheres, exhaust protectors may be used in vibrators with tapped exhaust ports to prevent internal contamination of the vibrator.

- Safety cable - Safety cables are recommended for all overhead vibrator installations.

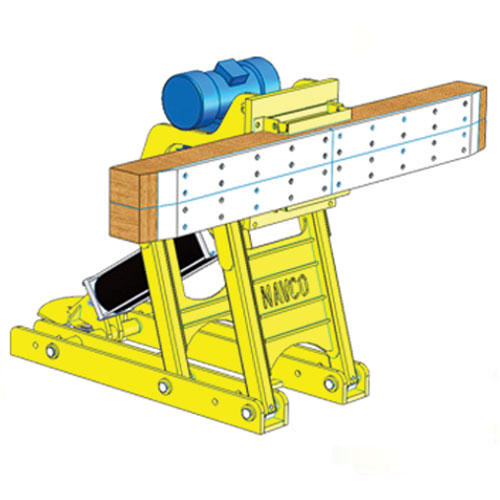

- Mounting accessories - T-Slotted Mounting Plate, Channel Mounting Plate, Slip Mounting Bracket and Pipe Mounting Bracket.

Products from KJN Enterprises

Vibratory Solution, Extendovibe

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads