Schedule a Call Back

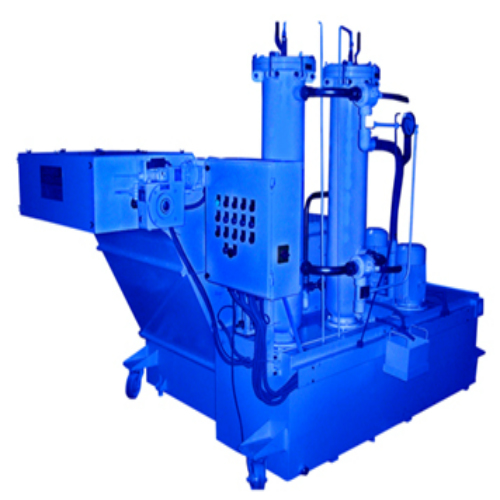

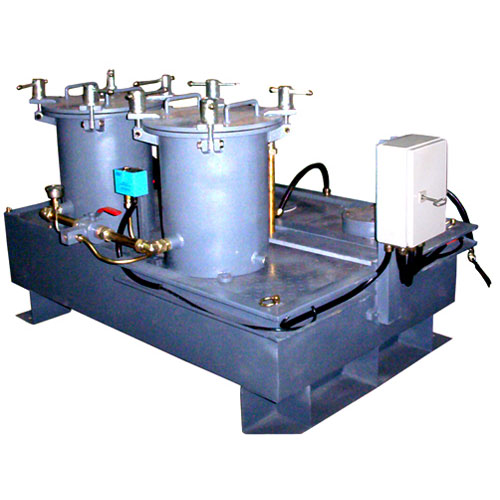

Filter, rotary drum universal

Filter, rotary drum universal

Rotary drum filters are specially designed to handle floating chips like aluminium, brass, cast iron, etc, which pose serious problems in filtering. Construction and operation: the filter can be directly connected to the machine outlet, through a chute from which the chips with coolant are discharged. The heavier chips are carried by a scraper conveying mechanism continuously. The coolant flows through a rotary drum, which has a fine stainless steel mesh around. After filtration, the coolant is collected in the integral clean coolant tank. The fine and floating particles get deposited on the drum. The continuous coolant jet diverted from the supply pump itself cleans the drum and the deposited chips are carried away by the scraper in the form of sludge. The system works on `upward flow' principle where the difference in level of coolant is used for siphon action. The system is available in flow rates of 100 LPM to 1000 LPM. 2, 3 or 4 pumps with different flow rate and pressure can be supplied as per customer requirements.

Product & Technology News

Products from Universal Group of Industries

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads