Schedule a Call Back

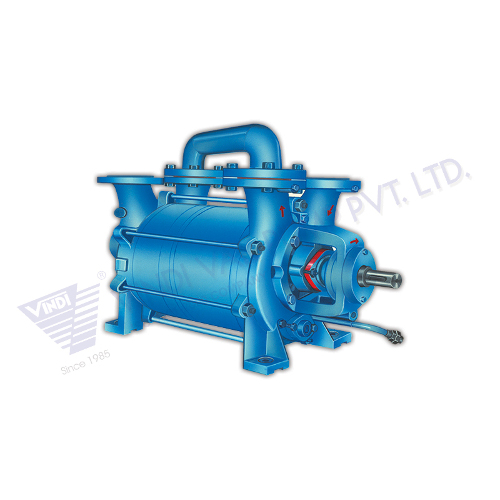

Two Stage Liquid Ring Vacuum Pump

Two Stage Liquid Ring Vacuum Pump

Vindi Vak Pump Private Limited offers Two Stage Liquid Ring Vacuum Pump. The Liquid ring vacuum pump is the best solution for vacuum applications where wet, or extremely humid, and slightly contaminated gases are ingested. For several of these applications, water is the best media that can be used for the liquid ring. Vindi Vak Pumps, India is one of the leading manufacturers of liquid ring vacuum pumps with single stage (RT Series) & two stages (RTS Series) designs. With the experience developed over decades of engineering research, continual in the latest technologically advanced machinery, and sound mechanical know-how, Vindi Pumps’ product is synonymous with high quality, high efficiency, robust construction and maximum reliability. Two stage vacuum pumps typically produce vacuum to 720 mm of hg, assuming air is being pumped and the seal-liquid water at 30°C (85F) or less. Dry air and 30°C water temperature is the standard performance basis which most manufacturers use for their performance curves. The smallest Vacuum Pump is having full open suction capacity of 120 M3/Hr and is being driven with 7.5 HP Electric Motor. While the biggest model of Vacuum pump is having full open suction capacity of 625 m3/hr and is being driven with 30 HP Electric Motor.

Product & Technology News

- Power Industry: Pneumatic conveying of fly ash, vacuum priming, vacuum deaeration and condenser initial evacuation.

- Sugar & Distillery Industries: Vacuum filtration.

- Plastic Industries: Degassing, drying & conveying

- Environmental Industry: Vacuum priming, digester gas compression, waste water disposal.

- Petroleum Refining Industry: Crude oil stabilization, crude oil vacuum distillation, filtering / de-waxing.

- Paper & Pulp Industries: Process vacuum, stock & white water deaeration, head box compressor / vacuum pump.

- Printing Industry: Powdering on printing presses, screen printers, central system.

- Chemical Industry: Solvent recovery, vacuum filtration, vents gas compression.

- Pharmaceutical Industry: Drying, distillation, degassing.

- Packaging Industry: Vacuum packaging, production PET containers.

- Ceramic Industry: Air removal from clay, vacuum processing.

- Suitable for low and high vacuum applications

- Rugged construction for heavy duty application

- No metallic contact inside machine hence less wear & tear,

- Moist air, vapours, aggressive gases & dust laden gases can be handled

- No contamination of medium passing through

- Leak proof sealing arrangement can be done

- Clean & Oil free exhaust / discharge

- Compression takes place with small temperature rise.

- Compact unit due to direct drive

- Low Power and Water consumption.

Products from Vindi Vak Pump Private Limited

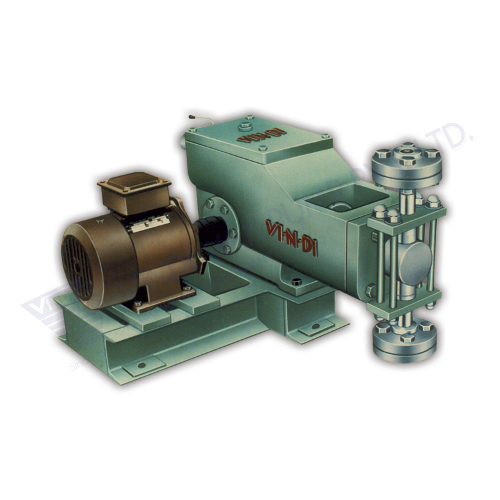

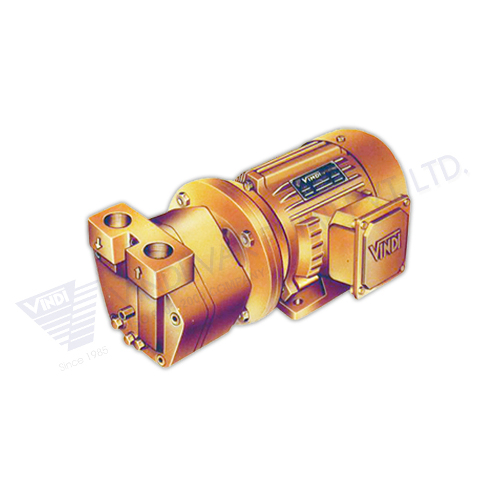

Monoblock And Closed Couple Vaccum Pump

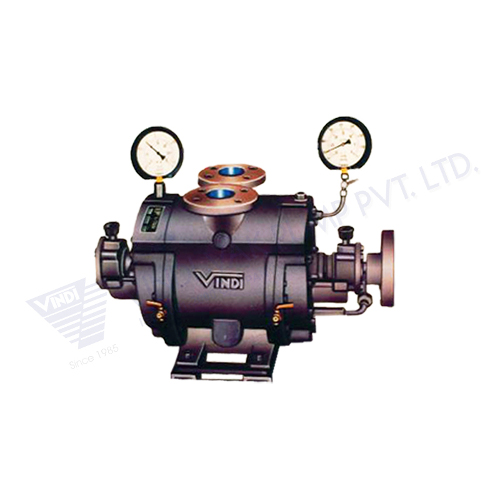

Single Stage Liquid Ring Vacuum Pump

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads