Schedule a Call Back

Track & Trace System

Track & Trace System

Acrifab Pvt Ltd. provides an extensive collection of Track And Trace System. These are manufactured as per industry standards and quality norms. Before the final delivery of the products, these are quality-tested by our experts. Our offered range of products widely find their applications in manufacturing various cosmetic product, cosmetic product machine, pharmaceuticals machinery, pharmaceutical product, beverage machine, beverage and pharmaceuticals row material.

Other information:

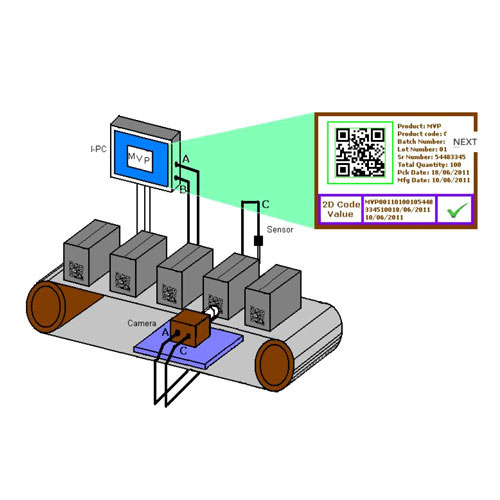

- Scanning and printing code with camera & store the data in data base

- Data base management

- Web application to enable track & trace

- Printing of this information on primary, secondary and tertiary packaging in form of 2 D Code (GS1 standard)

- In pharmaceutical industry track and trace technology is used mainly for tracing and tracking of export consignments of pharmaceutical products, generation of unique identification number

- Global server management

- SMS gateway for end user

Process involved:

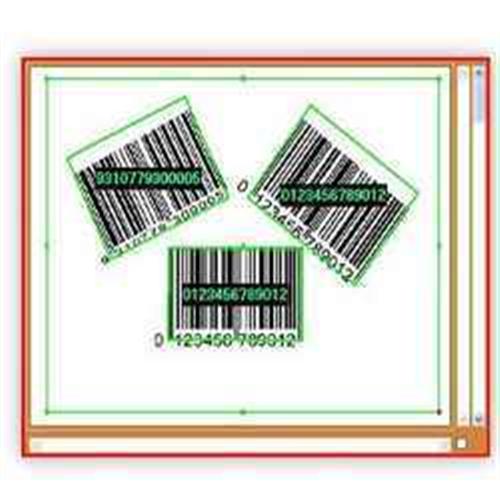

- Primary level packaging requirement: Incorporation of 2D (GS1 Data matrix) bar codes on medicines at strip/vial/bottle, etc. encoding unique product identification code (GTIN) and unique serial number of the primary pack

- Secondary level packaging requirement: Incorporation of bar codes (1D or 2 D) encoding unique product identification code (GTIN), batch number, expiry date and unique serial number of the secondary pack

- Tertiary level packaging requirement: Incorporation of bar codes (1 D) encoding unique product identification code (GTIN), batch number, expiry date and unique serial number of the tertiary pack (shipper/carton)

Technical specifications:

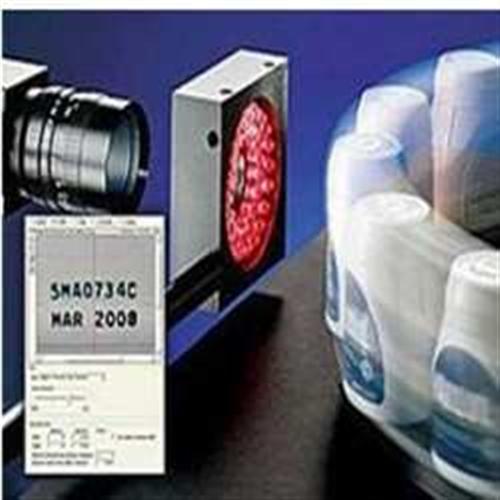

- High resolution ether-net camera

- The printed data may be fixed (static), incremental variable and random variable

- In case of static data, the data is fed once at the time of starting the batch

- Air/piston based rejection system

- Sensors

- The software, vision pharmaceutical plus is designed especially for pharma, beverage, cosmetic products and printing industries

- Camera transfers images to the industrial PC(I-PC)

- High Intensity Illumination

- Industrial PC with high configuration

- Camera, optics and illumination are used mainly for grabbing images of moving objects on the conveyor belt at high speed

- Mega-pixel vision optics

- Software generates rejection signal and transfers that signal to rejection system if product fails to fulfill pre-defined inspection criteria

- Rejection System may be Air based or Piston based, depending upon weight and dimension of the product. On receiving a rejection signal, rejection system rejects/sorts particular defective product from the production line

- The system is having Software for making decision according pre defined criteria

- A sensor is used to synchronize vision system with the machine

- The software I-PC, processes and inspects particular image of the product/object and check that inspection criteria are fulfilled or not

Product & Technology News

Products from Acrifab Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads