Schedule a Call Back

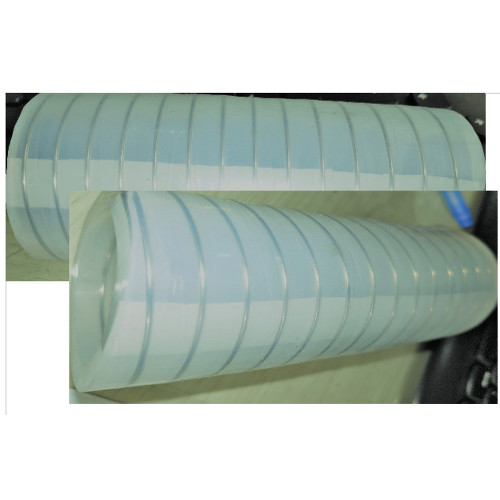

Silicone transparent tubings

Silicone transparent tubings

AMI Polymer offers its import substitute silicone transparent tubings of various sizes for food, pharma and medical application. This transparent tubing provides outstanding biocompatibility, having been subjected to 14 qualification tests and extensive laboratory testing. Cytotoxicity and heavy metal testing is also included in this. Silicone tubings are ideally suited for exacting medical, pharmaceuticals and industrial application like pharmaceutical transfer, peristatic pumping, laboratory, clinical, hospital application involving body tissues and fluids. These tubings are manufactured under strict good manufacturing practices (GMP) in a registered medical device facility. The material easily meets or even exceeds class VI requirement. Silicone transparent tubing can be sterilized by steam (30 min/121 C/15 PSI or 10 min/132 C/30 PSI), dry heat, ethylene oxide (ETO) or gamma radiation (2.5 megarads of exposure cumulative). The following are the distinguished features: non-reactive to body tissue and fluid; non-adherence to tissue; unaffected by most waters soluble materials; made from medical grade silicones which conforms to USP class VI requirement and complies with FDA 21 CFR 77.2600; sterilisable by steam, ethylene oxide (ETO), gamma radiation; temperature resistant from -80?C to 250?C; resists oxidation, ozone radiation and sunlight; and does not support bacterial growth.

Products from Ami Polymer Private Limited

Inflatable Seals Gaskets, Imaseal

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads