Schedule a Call Back

Studer unveils internal cylindrical grinding machine

Articles

Articles- Jun 19,24

Related Stories

Wall putty manufacturing: Processes and quality assurance

Birla White Wall Care Putty combines premium white cement with advanced additives, ensuring superior adhesion, water resistance, and a smooth finish.

Read more

United Grinding Group expands product portfolio through acquisition

The United Grinding Group intends to acquire the GF Machining Solutions Division (GFMS) of Georg Fischer AG (GF), Schaffhausen (Switzerland).

Read more

United Grinding Group unveils umati; to help machines connect easily

The UNITED GRINDING Group uses umati to connect various machines easily, including older ones, in their production environment.

Read moreRelated Products

Turning Tools

Duracarb Cutting Tools offers a wide range of Turning

Tools.

Carbide Burrs

SRT Industrial Tools & Equipments offers a wide range of carbide burrs.

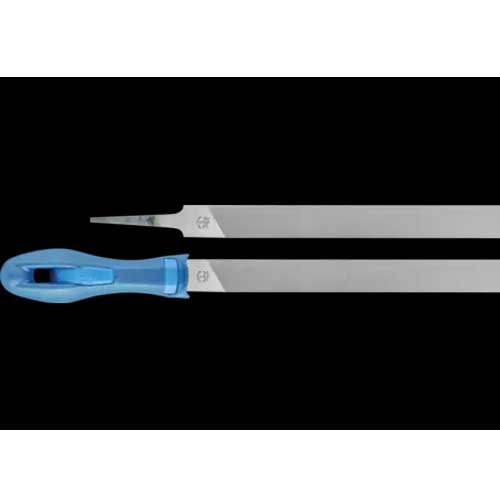

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.