Schedule a Call Back

Industrial Impellers

Industrial Impellers

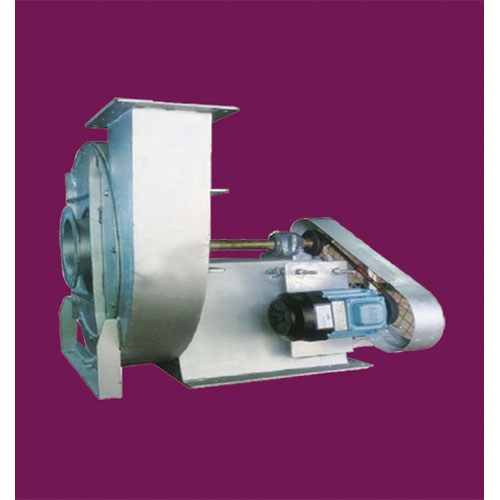

Indair offers a range of Industrial Impellers. Backward inclined, backward curved blades, is a highly efficient impeller design. It is employed to handle air and also used for gas medium containing lighter amounts of dust particles and at high temperatures. Reinforcements and surface hardening are done for extra strength, if required. Backward inclined, flat blades make efficient and strong shape design, and a cost-effective alternative to the backward curved design but with flat blades instead of curved and radial tipped. This results in a slightly lower efficiency, compensated by handling moderate dust particles. Backward inclined, forward curved blades are mostly known as radial tipped blades, this design reduces the potential for dust build-up on the underside of the blades in applications with light or moderate amounts of gas-borne dust. Backward inclined, forward curved blade is an intermediate design for volume and pressure. Backward inclined, aerofoil blades – aerofoil bladed impellers are most commonly used in applications handling large volumes at low pressures. This highly efficient design of fan is used in clean air or with gases containing small amounts of erosive particles. Radial blades are blades running from hub to impeller tip without any curve or inclination essentially a large paddle wheel. This design results in a relatively inefficient fan with power consumption higher than that using the much more common backward inclined blade. Its mechanical strength and resistance to wear makes the fan to handle applications when high quantities of abrasive dust are present in the gas stream or when very high temperature in the gas is expected.Configurations: single or double inlet – a double inlet impeller consists of two single inlet impellers back to back on the shaft may or may not sharing a common back plate, providing almost double the flow of a single inlet fan. The selection of a double inlet fan results in a smaller diameter, compact compared to two single inlet fans. Hence a centrifugal fan has a descriptive term as SISW (single inlet single width) or DIDW (double inlet double width). Single or multiple stages - a multi-stage fan consists of two or more impellers mounted on the same shaft. The air or gas flow passes through each one in turn, with a consequent increase in pressure.

Product & Technology News

Products from Indair

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads