Schedule a Call Back

Spin Flash Dryer

Spin Flash Dryer

Raj Process Equipments And Systems has introduced a Spin Flash Dryer, developed in response to a demand by the chemical industry to produce uniform powder on a continuous basis from high viscosity fluids, cohesive pastes and sludges. Operation: a spin flash dryer produces powder from feed, which is viscous or gelatinous in nature, paste or filter cake. The two-step process involves disintegration of the feed and drying of the disintegrated feed. Depending upon the nature of the feed material, conventional arm design could be used for crystalline, non-sticky material or a specially engineered rotating spin design fan could be used to handle sticky and gelatinous materials. The disintegrated material is brought in contact with the hot drying media, which dries the particle and also pneumatically conveys it for separation in a cyclone or bag filter. A product classifier ensures desired size and the dried particles only leave the drying chamber. The very short residence time of one to three seconds requires that the moisture to be evaporated is truly surface water and that the particles in the feed cake are completely dispersed in the drying air. Otherwise, the larger particles in the feed material may require longer drying time than the smaller ones in order to reach the desired moisture content.

Product & Technology News

- Increased drying efficiency and low energy cost

- Direct drying with negligible diluting

- Non-stop processing with little drying time

- Least operator overheads and low maintenance cost

- Simple and robust design

- Special design of feeding system for critical and sticky products

- Pressure shock resistant for safe drying of organic products

- Available in GMP design

- Capacities are customer specific ranging from 5 kg/hr to 5000 kg/hr water evaporation

Products from Raj Process Equipments and Systems Private Limited

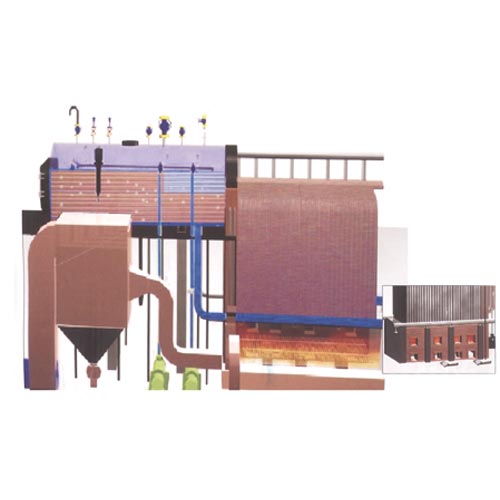

Package Boilers With Integral Furnace

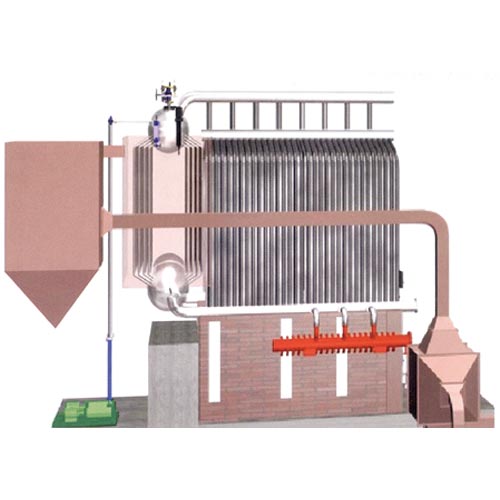

Package Boilers with External Furnace

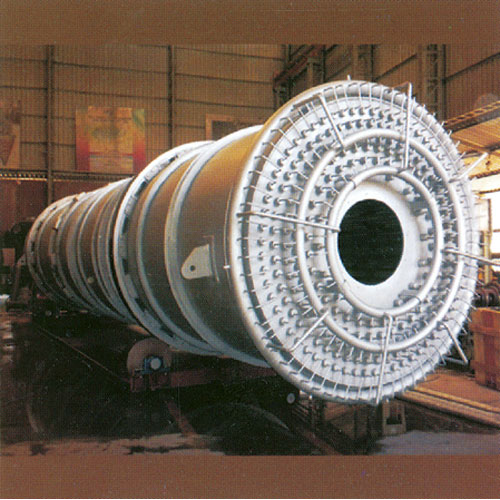

Captive Plant High Capacity Boilers

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads