Schedule a Call Back

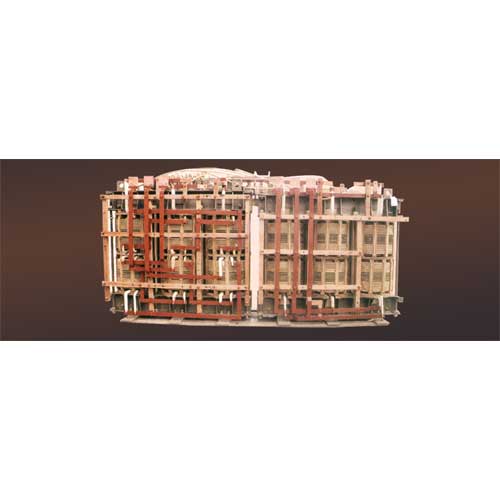

Dc Arc Ladle Refining Furnace

Dc Arc Ladle Refining Furnace

Ladle refining furnace (LRF) is used to desulphurise steel, reduce gas content and remove other impurities besides its application as buffer between melting and casting system. In absence of LRF, liquid steel is tapped at higher temperature from melting furnace resulting in higher power consumption, higher erosion of refractory and reduction in productivity in melting furnace. A combination of induction furnace and ladle refining furnace is an economical process of producing high quality alloy steel up to 30 tonnes. Arc furnaces are preferred for higher capacities as primary melters. LRF is purely a refining furnace. LRFs are of two types: double electrode, triple electrode. Dual electrode ladles are used for 10 to 50 tonne capacity on DC supply; triple electrode ladles are used for more than 15 tonne capacity on 3 phases AC supply. The power required in any arc LRF is 120-150 kVA per tonne of liquid metal. The temperature rise obtained in an LRF is 3-5°C/min. For 10-15 minutes, there is no temperature rise, as the input energy is used in increasing the temperature of the lining and additions. Flux addition is around 1-2% and alloys addition is also around 1-2%. Refining in LRF is generally completed in 30 to 50 minutes.

Product & Technology News

Products from Electrotherm (India) Limited

In Line Induction Heating System

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads