Schedule a Call Back

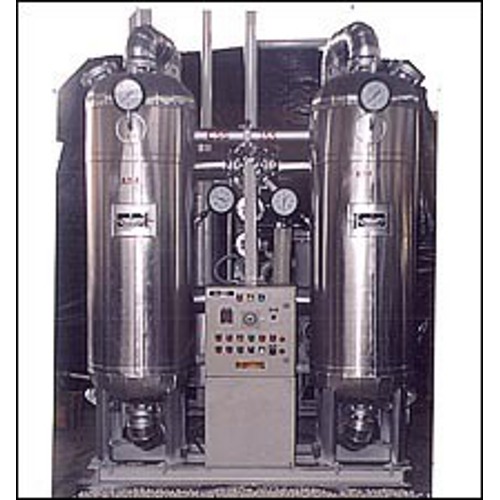

Air Dryer

Air Dryer

In a split flow – no purge loss air dryer, the wet air/gas stream is split at the air dryer inlet through a differential distributor valve. Part of this air/gas stream is passed through an external heater and heated to a regeneration temperature of 160-180°C, then it is fed to the adsorber desiccant Tower A containing silica gel or activated alumina/molecular sieves under regeneration thus removing out the moisture from the desiccant bed. A water cooled/air cooled after cooler condenses the desorbed moisture, which is discharged regularly through the automatic drain trap after condensation. This air/gas stream joins the main incoming air stream and goes for drying to the other Tower B under drying. Normally a cycle time of 8+8 hrs is utilised to complete one cycle of operation. After each operation the changeover is effected automatically. This type of dryer provides an outlet dew point of –40°C. The air dryer can be supplied with standard accessories like simplex/duplex pre-filters/after filters, flow meters, dew point meters, etc. The system is fully automatic/semi automatic, with timer/PLC controls with feedback to/from main DCS. Applications: instrument air dryers for power plants refineries and petrochemicals, chemical and fertilizer plants, etc. CNG compressed natural gas drying and conditioning plants, gas dryers, and hydrogen gas drier for generator cooling application.

Product & Technology News

Products from Mellcon Engineers Private Limited

Carbon Molecular Sieves for PSA N2 Gas Generators

Air Dryer, Heat Of Compression Type

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads