Schedule a Call Back

Ladle Refining Furnace

Ladle Refining Furnace

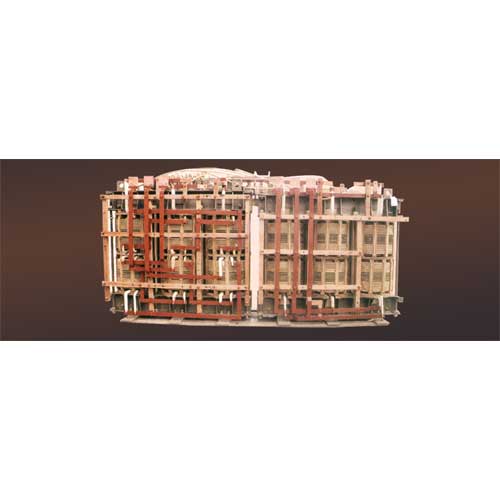

Electrotherm (India) offers a Ladle Refining Furnace (LRF) used to raise the temperature and adjust the chemical composition of molten steel. LRF desulphurises steel, removes other impurities and acts as a buffer between the melting and the casting equipment. LRF facilitates tapping at lower temperature, which in turn, increases production and refractory life of melting equipment and reduces power consumption, thereby reducing the cost of steel making. LRF provides greater flexibility to steel maker in overall plant operation. Ladle refining furnaces are used for the following refining processes: desulphurises steel up to 0.015%, removes metallic inclusions to make clean steel, reduces gas content by feeding aluminium/CaSi wire to produce “killed†steel; oxygen level of 30 ppm can be obtained; homogenises temperature and composition of molten steel by gentle stirring; helps achieve better recovery of ferro alloys; helps vacuum degassing treatment of steel to achieve low gas content (oxygen, nitrogen and hydrogen); and holds molten steel for sequencing on the CCM. Special attributes: use of servo valves and hydraulic cylinders for electrode regulation provides very precise control ensuring electrode consumption as low as 0.3 to 0.4 kg/tonne; use of ArCOS, Vatron-Austria make electrode regulation system provides impedance control, anti-resonant control, auto dead band adjustment, etc., ensuring precise control of power and virtually constant power from input; this reduces flicker, harmonics and improves power factor up to 0.89; ease in operation due to stationary electrode arms and moving ladle car, which is maintenance free and faster for taking sequence heat; and high level of automation through PLC. Once the process parameters are set, LRF operates automatically with high level of consistency, rate of superheating after stabilisation of temperature in the ladle can be up to 4.50°C/min. Use of gas control system, with imported flow meter, pressure control valves and flow control valves for argon purging minimises the use of argon gas and provides uniform temperature gradient through molten steel.

Product & Technology News

Products from Electrotherm (India) Limited

In Line Induction Heating System

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads