Schedule a Call Back

Bevel Gears

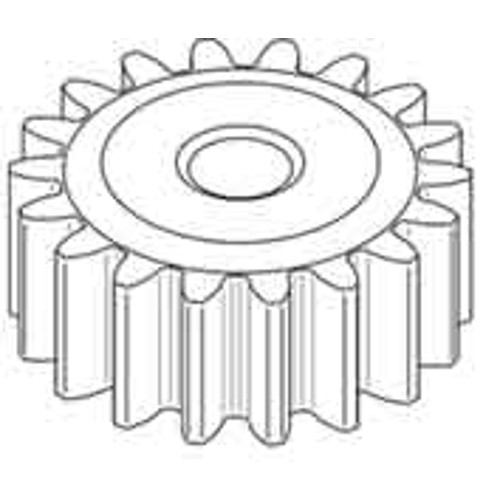

Bevel Gears

Revathi Power Transmission offers Bevel Gears. A Bevel Gear is shaped like a right circular cone with most of its tip cut off. When two bevel gears mesh their imaginary vertexes must occupy the same point. Their shaft axes also intersect at this point, forming an arbitrary non-straight angle between the shafts. The angle between the shafts can be anything except zero or 180 degrees. Bevel gears with equal numbers of teeth and shaft axes at 90 degrees are called miter gears. The teeth of a bevel gear may be straight-cut as with spur gears, or they may be cut in a variety of other shapes. Spiral bevel gears have teeth that are both curved along their (the tooth's) length; and set at an angle, analogously to the way helical gear teeth are set at an angle compared to spur gear teeth. Zero Bevel gears have teeth which are curved along their length, but not angled. Spiral bevel gears have the same advantages and disadvantages relative to their straight-cut cousins as helical gears do to spur gears. Straight bevel gears are generally used only at speeds below 5 m/s (1000 ft/min), or, for small gears, 1000 rpm.We manufactures all kinds of Bevel gears as per customer specification (standard / non-standard items).

Product & Technology News

Products from Revathi Power Transmission

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads