Schedule a Call Back

D.C.E.M. Brake Series, DMB

D.C.E.M. Brake Series, DMB

DMB Electro-magnetic shoe brakes are actuated by energy stored in the compression spring and is released by a do electro-magnet. Thus, the brake is fail-to-safety, and is normally ON (applied). The DC magnet coil, when energised releases the brake. This series of brakes are characterised by robust construction and design and are especially suited for Steel Mills, Hoists and Elevators. Construction: A pair of brake shoes with bolted brake liners is hinged in v-shaped grooves in cast steel arms. A strong DC electro-magnet is encased in a steel enclosure and is bolted on the base frame. The two moving parts of the magnet are hinged on the base frame. These are held apart by an air gap, and are stressed by a strong compression spring loaded by a torque-adjusting nut when the brake coil is not energised. The magnet body pulls the side arm by a tie-rod. The other half of the magnet body pushes the-main arm on the brake drum. The lower ends of the shoes are pressed against each other in a ball-and-vee shape arrangement for synchronising their movement. Operation: When the magnet coil is not energised, the brake liners are pressed on the brake drum due to the push-pull force exerted by the compression spring. When the coil is energised by a (220V) DC source, the two magnet bodies are attracted towards each other. This results in: Closing the air gap to zero; pushing of side arm away from the brake drum; releasing the pressure on the side arm and releasing the brake, brake drum; compressing the spring and storing energy for next braking cycle. This releases the brake. When the DC source is cut off by switching it off intentionally or by power failure, the magnet is de-magnetised, the energy stored in the coil spring is released, and the two magnet body parts move away from each other, the two arm close the brake shoes on the drum and the brake is applied. Features: robust construction and simple design; reliable and consistent braking torque; efficient distribution of forces; brake shoes replacement is easy and without dismantling; ease of torque adjustment.

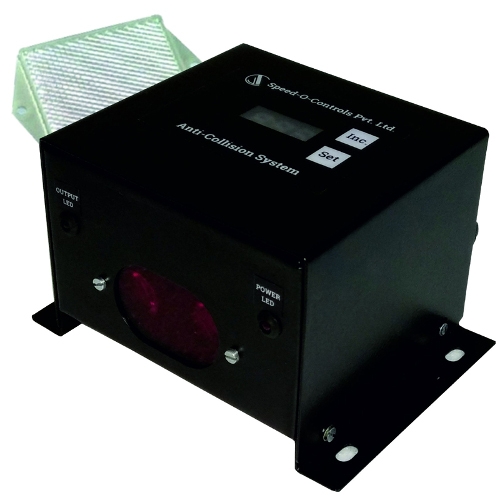

Products from Speed O Controls Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads