Schedule a Call Back

Water-cooled after coolers

Water-cooled after coolers

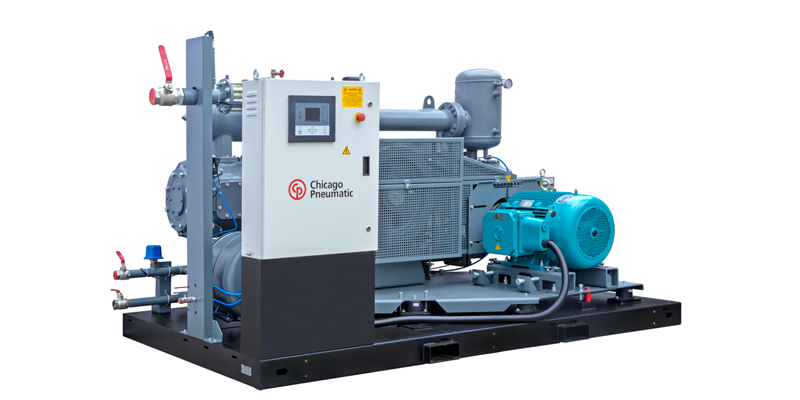

Aftercoolers perform two essential functions that provide the necessary first step in conditioning of compressed air. They reduce the temperature of air to a safe operating range as well as remove moisture condensed during the cooling process. These are of shell and tube construction with the air passing through the tubes and water flowing in the opposite direction in the shell. Closely spaced baffles and tube ensure high velocity and turbulence on both shell and tube sides as well use of high conductivity copper tubes, leads to high heat transfer efficiency. Moisture condensed in the cooling process is carried away with the air and is separated in a moisture separator bolted directly to the shell and tube assembly. A central baffle forces the air to change direction twice resulting in effective separation of the condensed moisture the collected moisture is periodically drained.