Schedule a Call Back

Turn/Mill & Grinder

Turn/Mill & Grinder

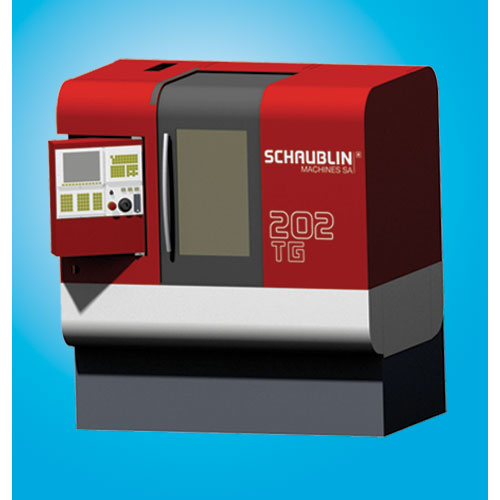

Schaublin Machines has launched a new 8-axis Turn/Mill and Grinder, Model 202TG. This is configured in several versions enabling hard turning, milling and grinding that offers impeccable precision levels for applications in the automotive, micro manufacturing, cutting tool, optical, aerospace, medical and defence industry sectors; such is its diverse capabilities. The machine can be used both for turning and grinding. It comes with a cast frame, a W25 headstock and two slides (X/Y axes). The user now has the possibility to perform his turning and grinding tasks on one single machine. However, the machine can also be used exclusively for grinding, be it external or internal grinding, all the more so as the protective devices of the machine have been especially designed for this type of machining. In addition, the 202 TG can be equipped with a bar loader (bar capacity Ø19 mm) or chucks as well as with various other options (tailstock centre, turret, grinding spindle, pockets, separators, etc), and thus can be tailored to the individual needs of each customer.

Product & Technology News

- Maximum turning diameter – 80 mm

- Turning length with collets W25 – 150 mm

- Spindle speed, infinitely variable – 50 -7,000 min-1

- Max bar capacity with W25 collet – 19 mm

- Torque continuous/intermittent – 26.1/35.1 Nm

- Stroke X1, X2/Z1, Z2 axis – 150 mm/300 mm