Schedule a Call Back

Titanium Diboride Powder

Titanium Diboride Powder

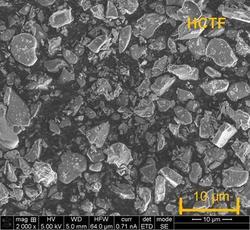

Titanium Diboride (Tib2) is produced by Momentive Performance Materials (Formerly GE Advanced Materials) using a continuous chemical process that

controls stoichiometry and particle size to create high purity powder. The shapes of the processed crystals are flat, hexagonal platelets.

When solidified into shapes, the resultant ceramic is electrically conductive, a property very rare among ceramic materials. This makes it valuable in

electrical applications and also enables it to be formed into complex shapes using electrical discharge machining (EDM). TiB2 combines superior

hardness and corrosion resistance with a high

melting point (>2900°C) and good oxidation resistance to 1000°C.

Key Properties

Extreme Hardness

Nearly as hard as diamond when sintered, TiB2 is tough enough to be used as military armor and improves the fracture toughness

of ceramic cutting tools and other components.

Electrical/Thermal Conductivity

As an excellent conductor of both electricity and heat, TiB2 is valuable in electronic and specialty applications. TiB2

enhances thermal conductivity when used as a filler in polymeric matrices.

Chemical Resistance

Titanium Diboride will not react with molten, nonferrous metals including Cu, Zn and Al. TiB2 is used as crucibles, vacuum

metallization components and electrodes for processing these materials.

Product & Technology News

- Electrically conductive composites such as aluminum evaporation boats

- Complex, sinterable TiB2 shapes

- Additives for producing specialty ceramic composite materials

- Refractory material and antioxidant additive that is nonreactive to most molten nonferrous metals and alloys

- Thermal management materials