Schedule a Call Back

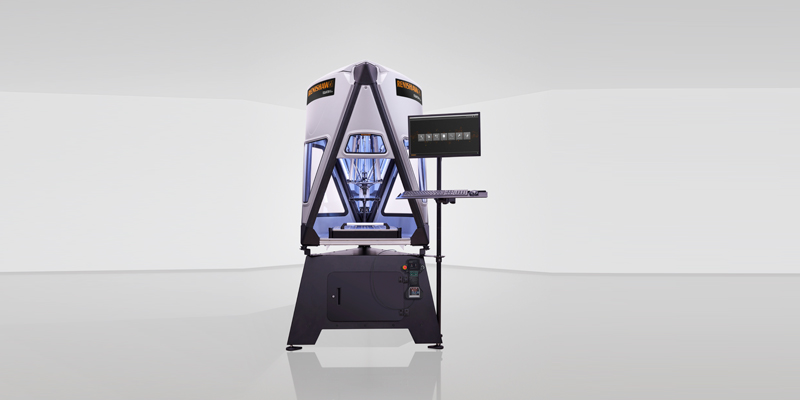

Surface Finish Measuring Machine, 5-Axis

Surface Finish Measuring Machine, 5-Axis

Carl Zeiss offers a fully automated 5-axis Surface Finish Measuring Machine. Now one can measure surface roughness and waviness in complicated components like cylinder heads, cylinder blocks, crankshafts, camshafts, unmanned in single set-up. This is a flexible measuring station for contour measurements, designed for ease of use for efficiency. Among the top-of-the-line products being exhibited by Carl Zeiss in IMTEX-2012, Surfcom C5 stands out as the most advanced 5-axis CNC controlled surface roughness and waviness measuring instrument, with a capability of upgrading to 8-axis. Surfcom C5 allows customisation of the work-piece feed unit and thereby, making it the most versatile machine for completely automated surface roughness measurement of large components. For example, a cylinder head has approx 100 Surface Roughness measurements, which takes at least 6 hours by conventional method. This can be achieved in just 2 hours in C5.

Product & Technology News

- Angular rotation of the pick-up, allowing downward, upward and horizontal measuring

- Linear motor drive in X-axis for high speed movement and low vibration measuring

- CY-axis movement of 100 mm/s for column

- CZ-axis movement of 100 mm/s for column, makes it the most versatile and fast surface roughness measuring machine, which can measure all operations in one setting