Schedule a Call Back

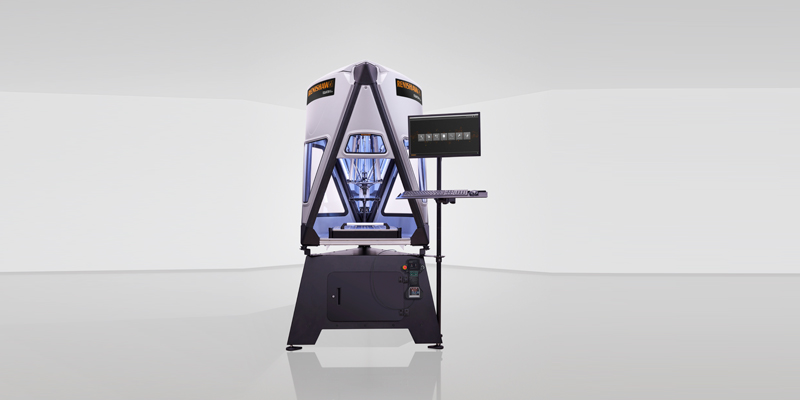

Single Flow Tube PTFE-PFA Rotameter

Single Flow Tube PTFE-PFA Rotameter

Structurally rigid materials such as PFA-clad aluminum KYNAR® surround wetted inert components. The resultant design represents a unique combination of a rugged, mechanically rigid frame and the chemically inert wetted parts. Flow meters are also resistant to external, ambient corrosives. For the protection of personnel, each flow meter is supplied with a safety shield. Rotameters are supplied with or without built-in needle valves and are panel mountable by means of KYNAR® panel nuts.

Principles Of Operation:

A cylindrical float freely moving inside a tapered flow tube comprises the flow measurement element of PTFE - PFA flow meters. The translucent PFA flow tube is installed vertically in-line in the liquid stream. As flow takes place, the float is propelled up inside the flow tube. The area between the float and the inside diameter of the flow tube gradually increases with the increasing flow. Correspondingly, the pressure lifting the float decreases until the weight of the float and its buoyant force come to equilibrium. At this point, the top of the float is lined up with a scale graduation on the flow tube denoting a discrete rate of flow.

Materials Of Construction:

- Flow tubes PTFE, PFA floats PTFE front shield polycarbonate

- Wetted parts PFA (flow tubes) and PTFE (end fittings and floats) and PCTFE (guide rods)

- Connections 1/4 inch fnpt to 3/4 inch fnpt based on model selected

Product & Technology News

- Scales 0 to 10 markings

- Standard accuracy ±5% fs maximum operating pressure 100 psig (6.7 bars)

- Maximum operating temperature 250°f (121°c)

- Leak integrity individually leak tested and certified to a rating of 1 x 10-7 sccs of helium