Schedule a Call Back

Rotary Transfer Machines

Rotary Transfer Machines

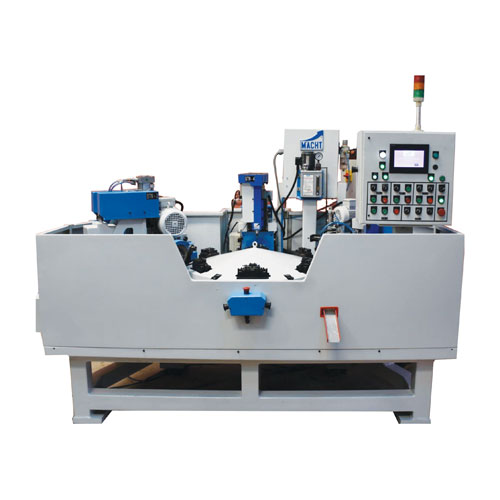

MACHT Technologies (P) Ltd has launched its new generation Rotary Transfer Machines built for high accuracy and high volume parts. Rotary transfer machine or dial indexer machines are ideal for high volume parts where in different operation is performed on the component at every subsequent station. This concept not only masks the loading unloading time but also limits the cycle time for the part to the longest machining time on a particular station.

These are multi station and multi operation machines equipped with a rotary table. The machining operations on a component are broken down to stages and are planned sequentially around the rotary indexing system on different stations of the machine. Therefore the cycle time of the component is dependent on the longest machining time on any of the stations on the machine. Even loading/unloading is performed during the machining is being performed at the various stations on the machine. Every indexing a finish component comes out of the machine.

With the advances made in control systems the company is in a position to offer multi-axes machines to customers and make the machine more flexible to accommodate a family of parts rather than dedicating them to a particular part. As most of the operations are performed in single clamping the accuracies achieved are also very good.

These machines are mostly equipped with modular units of MACHT design and make, and some of the important units are:

- Servo controlled rotary indexing table – this servo based rotary indexing table is the company’s in-house development, which is fitted with Hirth coupling for better accuracies and rigidity; the table is non lifting type which is an another plus

- Self centring clamping fixture – the pneumatic self centring fixture with very precise location and repeatability were developed for the machine, keeping the product accuracies in mind

- ISO 30 milling spindle head – the standard slide mounted spindle head, which is highly precise and robust mounted on a vertical slide for form milling

- Pneumatic self feed spindle heads – standard pneumatic self feed spindles are work horses for any machine and are less to none in performance, and

- Servo self feed spindle unit – the next-gen of servo self feed spindle units, MSSF 3-60, developed by MACHT in 2012-13 have been in operation at various customers’ since last 3 years and are performing really well. With precision and speeds to match with the worlds best these produce precise holes at very short span of time.

A video presentation of this machine is available ion youtube, which gives a very good idea of its functioning. The company “Specialises in Specials” so if any customer product requires a different approach of machining it has the capability to provide the required solution for the same.