Schedule a Call Back

Rotan HD Series Pump

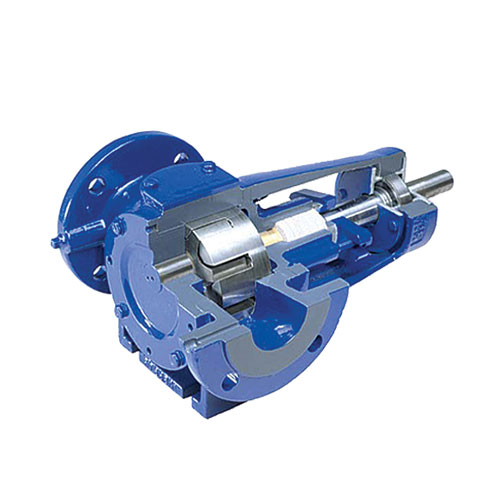

Rotan HD Series Pump

DESMI Pumping Technology A/s offers Rotan Pumps HD (Heavy Duty) series Pumps. Rugged, cast iron construction assures durability and extended operation life. They posses excellent vacuum capability and can operate bi-directionally. With two moving parts, the “gear-within-a-gear†principle ensures positive flow and low shear transmission of liquid. The simple design allows the pump to be adaptable to a wide range of applications, making the heavy-duty series ideal for pumping – oils, chocolate, soaps, paints, thinners, and other low to medium viscosity fluids.

With its modular configuration, Rotan pumps provide interchangeability of parts within the 11 different pump size variations. This permits easy conversion from a standard to a specialised pump. Furthermore, the “true†back pull-out design, when used in conjunction with spacer couplings, allows effortless disassembly/inspection of the unit without removing the casing from the process line, reducing down time. The three smaller size pumps are capable of pumping up to 30 GPM, and can be directly coupled to a 1200 or 1800 rpm motor. The larger 2â€, 2.5â€, and 3†ported pumps are available in capacities up to 130 GPM and can be coupled directly to 1200rpm motors. For the heaviest of applications, the 4â€, 5â€, 6â€, and 8†sizes are suited to pump up to 750 GPM.

Rotan pumps are backed by over 80 years of experience in the design and manufacturing of positive displacement pumps. With the company’s constant dedication to innovation and improvement, it’s no wonder the Rotan brand has been recognised as the most advanced internal gear pump available to the world today.

Product & Technology News

- Capacity range – up to 750 GPM

- Speed – up to 1800 GPM

- Differential pressure – up to 250 psi for sizes 26-81

- Up to 150 psi for sizes 101-201

- Suction lift – up to 15†Hg vacuum while priming and up to 24†Hg vacuum while pumping

- Viscosity range – .1 to 175,000 cSt (as standard) 32 to350,000 SSU (as standard)

- Temperature – up to 500°F

- Jacket Pressure – Up to 150 psi (as standard)

- Relief valve setting – approx 20 psi above system, design pressure is recommended

- Flexible sealing options

- “True†back pull-out design

- Opposing inlet and outlet connections with oversized ports

- Shaft supported by two ball bearings in single sealed configuration

- Self-priming with large suction capabilities

- Low NPSH requirements

- Self-draining top mounted integral safety relief valve

- No speed reduction required in six smaller sizes

- Complete heating/cooling jacketing available

- Parts interchangeability

- Performance and hydrostatic testing standard