Schedule a Call Back

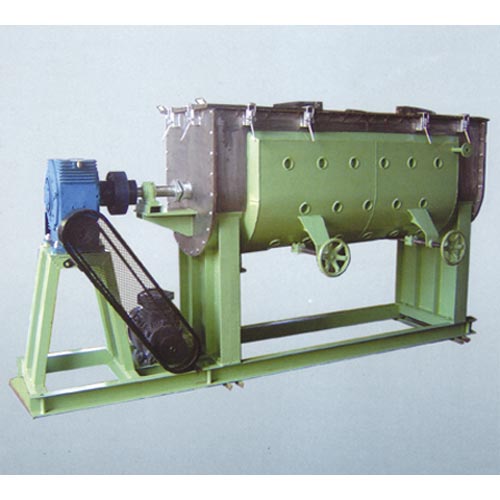

Ribbon Blender

Ribbon Blender

NSI Equipments Pvt Ltd offers a batch type Ribbon Blender. Its versatility for mixing solids and for combining mixing with heating, cooling, coating, and other processes makes it a real workhorse in the bulk solids processing application. The ribbon blender can also heat, cool or dry materials. Also it can coat solid particles with small amount of liquid to produce pigments, pharmaceuticals, chemical blending and other products. The ribbon blender, like all solid to solid mixers, operates by inducing one or a combination of diffusion, shear and convection. Small scale random motion called diffusion is easily achieved with free flowing ingredients in any mixer. Shear resulting from particle to agitator, particle to wall and particle to particle collisions. Large scale random motion called convection results when it is intermixed with large group of particles. The ability to provide high speed convective mixing is the ribbon blender’s real advantage among bulk solid mixers. In operation, ingredients are loaded into the blender its rated capacity. The company also offers Rotary Kilns, Rotary Driers, Basket Centrifuges, Bag Lift Top Discharge, Ball Mills, etc.

Product & Technology News

- hopper blades – 2 numbers moving at cutting speed, provided diagonally on opposite sides to break lumps/coarse particle of the mixer

- Liquid spraying nozzles with dozing system

- Nitrogen (N2) blanketing; pneumatically operated bottom valve

- he unit can be provided on load cells to weigh the mass accurately

- Jacket for heating and cooling