Schedule a Call Back

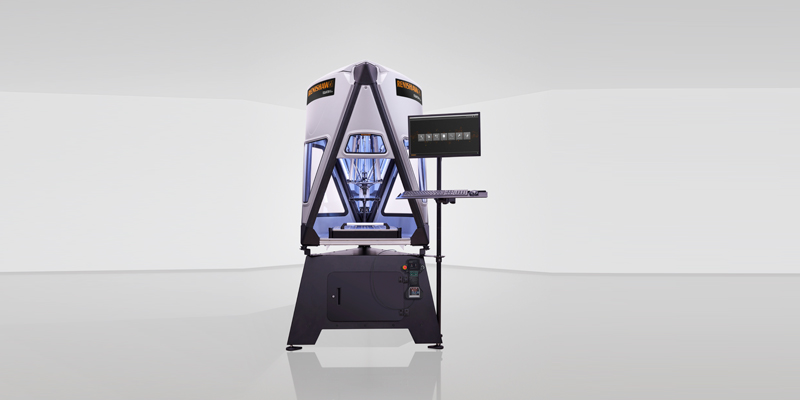

Rebound Resilience Tester

Rebound Resilience Tester

Zwick Rebound Resilience Tester serves not only for test instrument control, but also for data processing. The ratio between recovered energy and energy absorbed is digitally displayed and output, whereby the resolution remains constant for both low and high elasticity values. The absence of a dragpointer and the resulting friction means that a correction factor for determining the correct rebound resilience is not required. Conditioning hits, test hits, pendulum return, data acquisition and output are all performed automatically with the Zwick 5109 according to the selected test programme. The Rebound Resilience Tester consists of an adjustable rack for setting to various test piece thicknesses, a solid steel base, a test piece retaining clamp, a pendulum with impact-fin, automatic pendulum release and return unit, measurement and control processor with an electronic display of the rebound resilience. The sample retaining unit accommodates square test pieces of edge lengths 50 and 80 mm without deforming the test area. Impact fins of differing weights are available to enable the rebound resilience to different test standards to be determined. The protocol is printed out on a printer connected to the PC and contains the head data, details on the type of tester used, test parameters, results with details on tolerance limits and marking when these have been exceeded as well as statistics with histogram display. All data can be stored on flexible and hard disks and can be transferred to other computers.