Schedule a Call Back

Pluri Tubular Bags

Pluri Tubular Bags

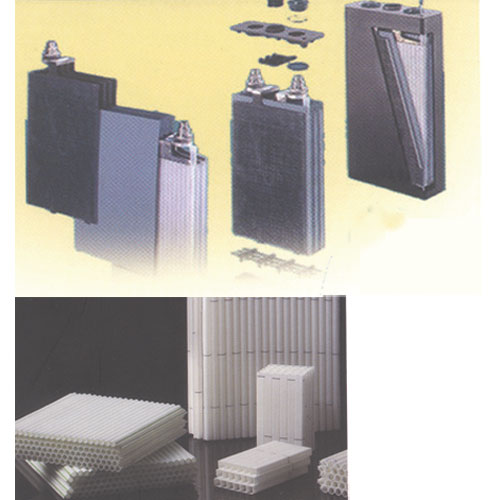

KE Technical Textiles Pvt Ltd offers a range of Pluri Tubular Bags, one of the most important components of positive plate of lead acid storage battery that plays a vital role in its performance. Considering this, special care is taken during the manufacture of pluri tubular or multi tubular bags. While designing the product it has taken into consideration the particle size of battery grade active material of 94% oxide content which varies from about 53 micron to as low as 35 micron. While identifying the raw material and optimisation of process parameters, it has considered the hazardous nature of chemical reaction, such as electro chemical oxidation, continuous exposure to battery grade sulphuric acid of 1.3 specific gravity at 70°C. Special weaving technique, improved coating mechanism and better fibre engineering takes care of change of the pressure caused due to change of the volume by 90% in the positive plate and 160% in the negative one of active material due to change of its molecular weight from 273 to 303 and vice versa during utilizing period of better, and also can achieve maximum utilisation of active material through the wall of the bag. The company manufactures woven gauntlets in domestic and export variety with uniform pore size and impregnated with specially developed acrylic resin. It has also recently launched non-woven gauntlets in India with the latest manufacturing technology imported from Europe. The non-woven gauntlets available are now only in 6.2 mm, 8.0 mm and 8.4 mm dia with maximum height of 800 mm. The company, formerly known as KE-Burgmann Fiber India Pvt Ltd, was part of an Indo-Danish joint venture, set up in the year 1991. In 2001 after financial and management restructuring, it became independent of its parent company. It manufactures technical textiles from fibreglass, polyester, nylon and other new generation synthetic yarn for use in lead acid batteries, high temperature, cryogenic, gaseous, corrosive and other hazardous industrial application areas. The company has its own facilities of weaving, processing and coating of fabric with various polymers and resin systems like PTFE, fluoro elastomers, acrylic resins, graphite, silicone phenolic resin, melamine, etc.