Schedule a Call Back

Plastic Mould Steels

Plastic Mould Steels

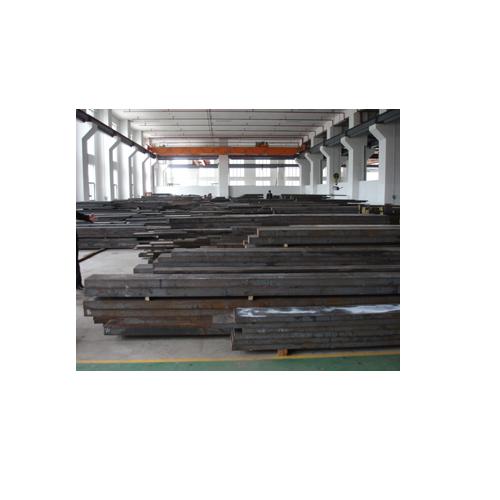

Goel Steel Company, an ISO 9001: 2008 certified company, offers a range of Plastic Mould Steels, which are mainly subjected to high pressure, wear, corrosion and elevated temperatures during operations.

The main properties in these steels are:

- Easy machinability

- Polishability

- High compressive strength

- Dimentional stability

- Corrosion resistance

The amount of abrasives added to the plastics (to improve the properties like hardness, etc., on the component) increases the wear on the mould steel. In such cases higher pressure is needed to mould these components, as such great care must be taken in choosing the right kind of steel. For lower abrasive plastics, DIN 1.2738 and DIN 1.2311 are good. While for medium abrasive level DIN 1.2344 is good. For higher abrasive plastics steels like DIN 1,2083, HPM38, DIN1, 2316, HPM77, DIN 1,2379, D2, SLD, etc., are recommended. Goel Steel Company was established in the year 1973 with sole aim of serving tool rooms with quality tool steel at reasonable price and the company has achieved a fair degree of success with numerous satisfied customers. Tool steel technologically has been constantly upgraded to improve tool life and cost effectiveness. Various parameters are employed to manufacture cleaner and pure tool steels to reduce downtime and increase tool life and dimensional accuracies. Keeping pace with this development, the company has added these upgraded steels in its stocking program to serve high quality demanding customers with quick deliveries.