Schedule a Call Back

Multislide Stamping & Forming Technology

Multislide Stamping & Forming Technology

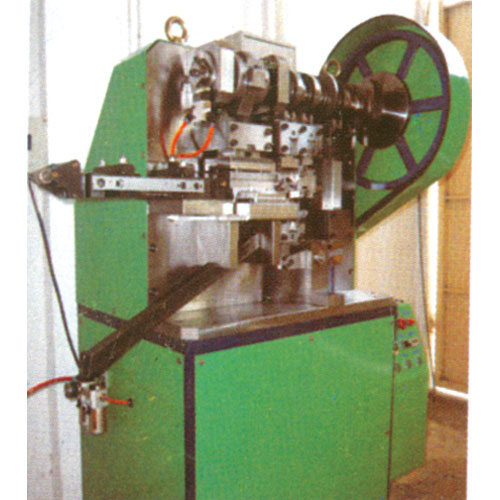

Ujwal Industries offers Multislide Stamping and Forming Technology, an advantage over traditional stamping processes. This reduces overall tool and part costs to alleviate the rising expenses in the company to be competitive in the market. The company offers this technology backed by 30 years of experience in this field. The machines are designed, built and tooled up in-house. This universally proven technology has been practiced in the USA and other European countries for over 50 years offering the following advantages:

- A favourable price/output ratio, parts production rate up to 250 strokes per minute

- Machine concept for punching, forming and bending

- Low tooling cost in comparison to expensive progressive dies

- Minimum tool development time

- Suitable for large production volumes, with minimum maintenance cost

- Suitable to produce wire and strip metal formed.

Outsourced process: Besides due development, the company also provides labour service to customers. It performs labour work as required, with raw material and or die given by customer.

Production: The company is able to undertake mass production with these presses having speed from 60 up to 600 strokes per minute. Assembly and finishing:Welding, brazing and other types of assembling as well as finishing like plating, heat treatment and others are done as per customers requirement.