Schedule a Call Back

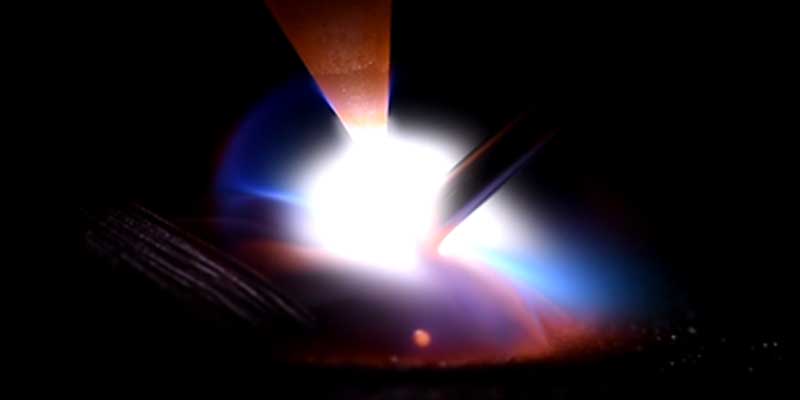

Laser Jewelry Welding Machine

Laser Jewelry Welding Machine

Materials with a high melting point as well as high heat conductivity can be welded using a laser. Laser welding systems are now used in many fields to efficiently, economically, and contactlessly make high-quality joints. They result in flawless seams in metal plates, plastic components, jewelry, and even building components.

Product & Technology News

- Laser spot welding used in jewelry and dental welding.

- Laser welding widely used in spot welding of micro precision parts, such as jewelry,batteries,IC lead,watch springs,tubes,electron gun assembly,and other areas.

| Laser Type | Nd:YAG Laser |

|---|---|

| Maximum Average Power | 200 W |

| Batter,welding frequency | 0.5-20 Hz |

| Wavelength | 1064 nm |

| Laser Class | IV |

| Max Pulse energy | 120J |

| Laser welding depth | 0.1-3.3 mm |

| Pulse width | 0.3-20 ms |

| Adjustable range of spot size | 0.2-3 mm |

| Ambient Temperature | 55°F (13°C) to 82°F (28°C) |

| Power Consumption | ≤ 5.5 KW |

| Electrical Connection | 230v/50Hz |

| Supplies | Xenon lamp,filter,protection lens,argon gas |

| Environment | Clean,no dust or less dust |

| Control system | Industrial computer |

- Mainly used for gold and silver jewelry to fill holes and welding slag. Machine has a wide application of uses and highly efficient.

- Laser spot welding is one of laser welding technology application's most important aspects, spot welding process is heat conduction, the laser radiation heats the surface driven by the internal diffusion and heat transfer by controlling the laser pulse width, energy, peak power and repetition frequency and other parameters,so that the piece melts and forms a specific pool.

- Laser spot welding machine has the character of high speed, high efficiency, depth, non-deformation quality ,and thermal impact on small area . High quality welding, weld formation, spot clean, efficient and environmentally friendly, without solder wire and so on.

- Better cooling chamber & efficient air cooling system.

- Low noise and low maintenance.