Schedule a Call Back

Gyratory Compactor

Gyratory Compactor

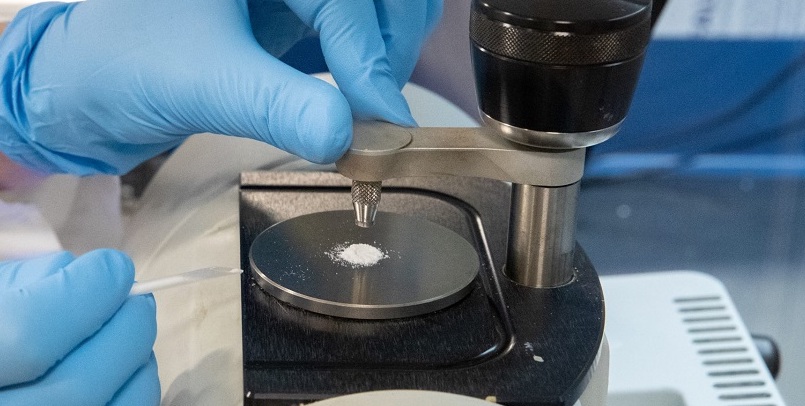

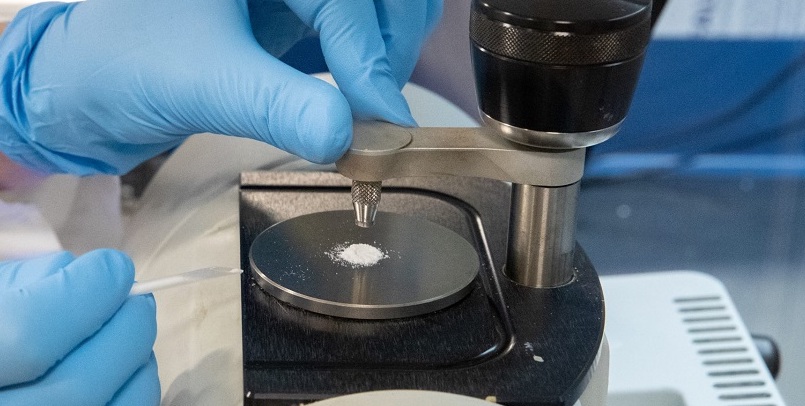

Taisei Trading Private Limited / Sinfonia Technology offers Gyratory Compactor.

A high quality machine with which the user can easily and safely obtain accurate, repeatable results day after day.

Gyratory Compaction is considered to be one of the best methods of laboratory compaction for the assessment of compactibility and the manufacture of test specimens.

Compaction is achieved by the application of a vertical stress (normally 600 kPa) via end platens to a known mass of asphaltic mixture within a 100 or 150mm internal Ø mould. The longitudinal axis of the mould is rotated (gyrated) at a fixed angle to the vertical whilst the platens are kept parallel and horizontal. During compaction the height of the sample is automatically measured and both the mixture density and void content calculated. The compaction progresses and it is also saved in Microsoft ExcelTM compatible format. The operator can choose whether to compact for a certain number of gyrations or until a target mixture density or void content is achieved.

Problems with existing compactors are mainly related to build quality and ease of use. Unlike most compactors 100 and 150mm Ø moulds can be tested without changing machine parts. A filled gyratory compactor mould is heavy and often very hot. In many cases these moulds have to be lifted in and out of gyratory compactors. With the Gyratory Compactor CRT–GYR–EN, no lifting of filled moulds is required. They are automatically lowered into position for compaction and then lifted up again for transfer to the integrated demoulding system. See what CRT-GYR asphalt compaction configurations Cooper suggests.

Standards:

Product & Technology News

- Compaction of asphaltic paving material to a target mixture density or void content

- Assessment of mixture compactibility

- SHRP Superpave asphalt mixture design

- Preparation of cylindrical test specimens

- Set up to comply with EN 12697–10 and EN 12697–31

- Can be configured to comply with SHRP Superpave, ASTM, AASHTO specifications

- Automatic mould insertion and retraction

- 150mm and 100mm internal Ø moulds can be tested without changing parts

- Cold mix (emulsion) materials can be compacted and the expelled fluid collected

- USB link with data acquisition and control system so that desktop can be used as host computer

- User friendly LabVIEWTM software displays results in real time

- Compaction data stored in Microsoft Excelâ„¢ compatible format

- Machine calibrated with traceable equipment

- Option for mould up to 300 mm high