Schedule a Call Back

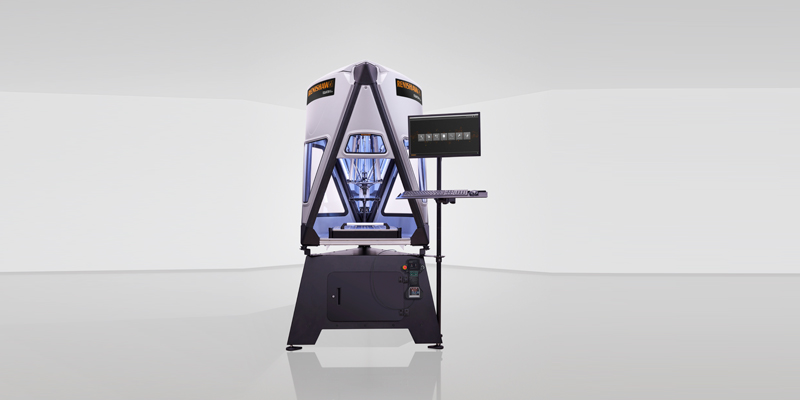

Foam Bath

Foam Bath

Foaming of lubricating oils in applications involving turbulence, high-speed gearing or high volume pumping can cause inadequate lubrication, cavitations, overflow and premature oxidation. The sample is blown with a controlled volume of air at different specified temperatures. The resultant foam is measured at the end of each aeration period and at different intervals afterward.

- Rectangular single / double foam test model with double walled construction with toughened glass observation window (75W x 385H mm) suitable for 1, 2 & 3 sequence.

- Illumination at rear.

- Stirrer, heater and cooling coil installed in each bath.

- This method consists of single / two test bath large enough to permit immersion of 1000ml-graduated cylinder.

- Digital temperature controller with PT-100 sensor. · The gas diffuser is of 1” dia spherical made up to crystalline alumina grain. · Air flow meter with needle valve to maintain an airflow rate of 94 ± 5ml/min through the gas diffuser stone.

- Diffuser arrangement consists of diffuser stone, air tube and gasket.

- Electric air compressor diaphragm type.

- Temperature accuracy: 24°C, + 0.5°C & 93.5°C, ± 0.5°C.

- Power supply: 220 V, 1 Phase, and 50 Hz.