Schedule a Call Back

Flush Bottom Valves

Flush Bottom Valves

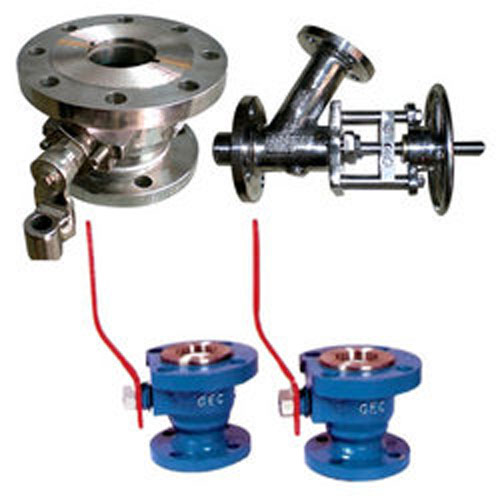

Flush Bottom Valves manufactured by General Engineering Consortium. Valves can be offered with pneumatic & electric actuators fitted with FLP solenoid valve & limit switches with manual override (for power or air failure). These valves are provided with temperature sensor arrangement. We offer our customers highly sophisticated and useful Flush Bottom Valves that are renowned for their Plug type design which makes them suitable for high temperature application. These valves offer non rotating type spindle in plug design, which reduces gland pack damages since shaft reciprocates.

We are a leading manufacturer, supplier and exporter of quality Industrial Valves and Automation Products. Our products are highly acclaimed all around the world for their robust nature, sturdiness and long life cycle. The wide range of Industrial Valves that we offer to our customers includes Knife Gate Valves, Flush Bottom Valves, Needle Valves, Ball Valves, Wafer check Valves, Cast Steel Valves (Gate ,Globe & Check Valves) and Butterfly Valves. Our products are noted for their longer service life and high strength with resistance to any kind of corrosion or degradation in quality. The material used to manufacture our products are of supreme quality and and help in rendering a timeless strength to these products.

Product & Technology News

- Pharmaceuticals and bulk drugs & heavy chemicals

- Hydrogenators, pressure vessels, & autoclave

- Design standard: BS and GEC

- Type: Plug, Ram (Non clog) & Ball

- Size range: 25mm to 150mm

- Pressure rating: 150, 300 and 600

- End connections: screwed and flanged ends

- Materials: SS304, SS316, Alloy-20, Hast–C, etc

- 100% tight shut off Valves

- Plug & Ram type - Y type design for liquids & slurry application

- Ram type valve is non-clog; Ram travels downwards for opening which is suitable for slurry & powder application

- Plug type design for high temperature application - plus350ºC

- Multiple seats (En caged), which makes valve 100% tight shut off even at 100 bar pressure

- U & V Type of gland packing design for zero leakage which makes most suitable for hydrogenators