Schedule a Call Back

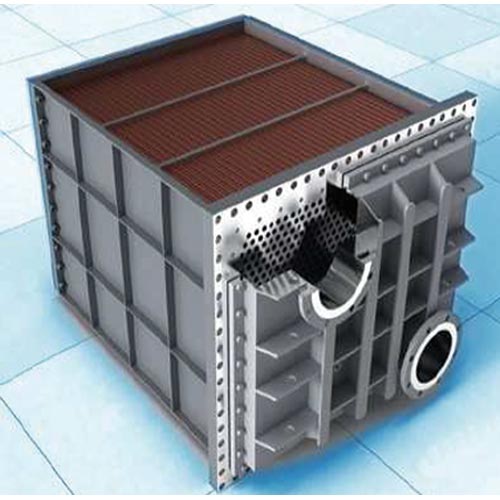

Finned Tube Heat Exchangers

Finned Tube Heat Exchangers

Kasera Heat Transfer Pvt Ltd offers a range of Finned Tube Heat Exchangers. This range of extended surface and finned tube heat exchangers is particularly suited for heating, cooling, air conditioning and industrial drying applications utilising steam, water and thermal transfer oils etc. All heat exchangers are designed and manufactured to meet specific requirements, hydraulically tested prior to dispatch to a minimum 35 bar (g) unless otherwise specified and manufacturers test certificates issued accordingly. HVAC heat recovery application: the heat exchanger installed in a ventilation system recovers the heat from the stale outgoing air and transfers it to the fresh incoming air. It is simple, yet effective way of providing continuous fresh air in the building throughout the winter and summer. Industrial heat recovery applications: because industrial applications have higher exhaust temperatures, they waste more heat and thus have greater waste heat recovery value. In addition of having higher exhaust temperatures, many industrial applications are in operation 24 hours a day, 7 days a week. It is for these reasons that exchanger has designed recovery units to meet these requirements. Industrial heat pipe exchanger are designed to operate in exhaust applications up to 450°F (232°C), and because they are available with an Heresite coating they can operate in otherwise corrosive environments. Return to process heat recovery: heat from the exhaust is recovered and returned as preheated air to the process (oven, dryer, etc). Process to process heat recovery: recovered heat from one process is returned to another process or heating system. It is sometimes possible to completely heat a second process with the recovered heat from the first and totally eliminating power source. Air dehumidification for air-conditioning: the U-shaped dehumidifier heat pipe increases the moisture removal capabilities of an air-conditioning system and eliminates the need for reheat overcooled air. The U-shaped exchanger precools air close to its dew point before entering the cooling coil. After that, the second section of the exchanger will reheat air up to a comfortable temperature. This process of precool and reheat air is done without the use of energy or pumps. The U-shaped exchanger will reduce the tonnage of the system and provide a lower operating cost.