Schedule a Call Back

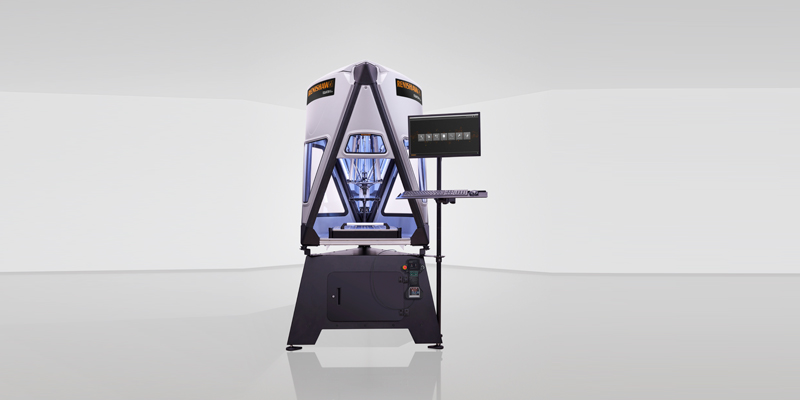

Dynamic Hardness Tester

Dynamic Hardness Tester

Hitech India Equipments offers dynamic hardness tester.

Product & Technology News

- A carbide tipped shuttle with a definite kinetic energy is impacted on the specimen; a part of this energy absorbed by the specimen and is a function of the hardness of the specimen.

- A tubular device housing electrodynamic energy measuring device carries out the impacting of the shuttle; a measuring instrument receives the signal, equivalent to absorbed energy, through a cable and displays with instant calculations.

- This displays dynamic hardness (D), a three-digit figure which is proportional to the hardness of the specimen.

- The machine has built-in conversion facility for given materials to convert 'D' value to Vickers, Rockwell, or Brinell scales which can be selected by pressing up/down keys; sleek and handy design, comes in a slim carrying case.

- Alpha numeric display indicates selected material and scale combination and hardness value; average key to select average of 2 to 10 readings; machine has improved electronics with micro controller circuitry and user friendly software; 30 hardness scales for different probes selectable by feather touch keys

- Auto detection of probe facility; automatic shutdown facility when machine is not in use for 10 minutes; this model operates on two pencil cells; printing is possible with all types of ports i.e. dot matrix (centronic parallel port); up to 999 readings can be stored in memory of the machine

- Low test expenditure; five numbers of probes can be given in different combinations; e.g. D1, D2, G1, G2 & C, * D 1, D2, D3, D4 & D5, * D1, D2, G1, SH &C; conversion of UTS facility is available on display by using side keys; this is applicable for only BHN scale for the range 226 to 634 BHN (hard steel and hard alloys only)

- In this model both serial and printer interfaces are available on single port (serial interfaces is an extra accessory); automatic calibration facility of probe is available through keyboard; serial interface is possible with RS 232.

- Data entry and datawise printout facility is available; the readings can be recalled one by one by using arrow keys on display in display result mode; backlight on/off facility is given by using arrow keys on keyboard.