Schedule a Call Back

Density Measurement System

Density Measurement System

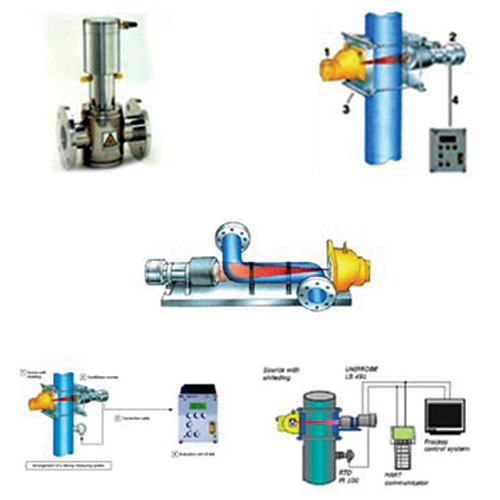

Berthold Technologies (India) Pvt Ltd offers a Density Measurement System. This contact less and continuous measurement system for the density of liquids or bulk material is requested in even more than the following applications: concentration measurement of acid, alkali, saline solution and suspension; crystallisation and polymerisation monitoring; determination of the solid matter content in slurries, in flue gas desulphurisation suspensions, in aluminium production and in mining; and measurement of the bulk density in washing powder and clinker. Measuring principle: the density measurement operates according to the physical law of attenuation of gamma radiation, which is dependent from the radiation energy, the measuring path length and the density of the irradiated product. Through keeping the energy constant and since the measurement takes place in a pipeline, so the measuring path’s length is also constant, the attenuation is only dependent from the applicable density of the measured product. The radiation intensity, received from a sealed and shielded source is measured by a most sensitive scintillation detector and this measuring signal is then converted to a density or concentration measurement signal by the corresponding evaluation unit. Dependent from the desired measuring range and accuracy and the products specification, the ideal irradiation angle is selected or a measuring path is used. Measurement is independent of colour, viscosity, conductivity and most chemical properties of the product. Berthold Technologies (India) is recognised as one of the most reliable suppliers, dealers and marketers representing the process measuring systems and equipment from Berthold Technology GmbH – Germany. The range includes: density measurement tool, level measurement, moisture measurement, concentration measurement, nucleonic measurement, radiometric measurement, bulk flow measurement system, microwave concentration measurement, and other non-contact measurement equipments for cement, sugar and steel.

Advantages:

- Non-contact, continuous measurement of density or concentration

- Adaptable to all pipelines from 25 to 1000 mm

- Most simple installation on existing pipelines

- Measurement in vessels also possible

- Lowest source activity

- Automatic decay compensation

- High long-term stability due to electronic compensation of temperature and ageing influences

- On line measurement

- No moving parts

- Reliable technology

- Low maintenance

- Easy to calibrate.

Product & Technology News

- Chemicals

- Food and beverages

- Petrochemicals

- Power plants

- Pulp and paper

- Cement and ceramics

- Mining

- Coal

- Iron and steel, etc.