Schedule a Call Back

Cutting & Grinding Oil

Cutting & Grinding Oil

Yushiro Buhmwoo (India) Company, an ISO 9001 & 14001 TUV certified company incorporated in 2005, is an MNC engaged in the field of manufacturing metal working lubricants. The parent company M/s Buhmwoo Chemicals Industry Ltd, Korea, is a leader in the field of manufacturing industrial coolants in Korea, with plants in Romania, Slovakia, Egypt, China, Thailand, Malaysia, Vietnam, Indonesia, Japan and USA. Buhmwoo Chemicals Industry joined hands with Yushiro Chemical Industry Ltd, Japan, who is also in the same field. With commercial production commenced in the month of May 2007, currently it manufactures hydraulic oil, way lube oil, gear oil, spindle oil, vacuum oil, compressor oil, cutting oil, press oil, cleaning oil, anti-rusting oil and discharging oil. Other than these main products, it also manufactures specialty products like orchard spray oil and knitting oil. Apart from the above mentioned oils, the company is importing heat treatment oil, rolling oil, automotive rust preventives and grease directly from the parent company, as per customers’ needs and requirements, and provide technical support on weekly basis. It caters mostly to automobile and engineering industries.

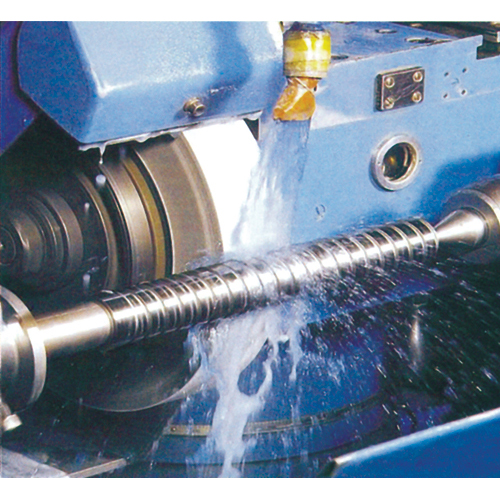

What is cutting/grinding oil?

Cutting is the process which is most widely carried out in several metal working industries. It is a process, which is carried out in a metal industry to get the specified shape and dimension of the end product. Cutting is done by a cutting tool, which is normally harder than the component or work piece. The main reason for tool damage is due to high temperature generated during the cutting process by the frictional forces between the tool and the job. In order to reduce the temperature, water was used for cooling, by pouring water at the cutting point. This process of cooling increased tool life, but had other problems like finish roughness, rusting property, etc. But nowadays research and development has proved that both oil and water at different ratios helps to solve these problems. By experience, it was noticed that the tool life and the required finish could be obtained by using water-soluble type coolant with the combination of water and oil. Cutting oil gives the secondary effects like chip removal and short-term anti-rusting property for the work pieces. Cutting & Grinding Oil.

Selection of industrial water

The quality of industrial water is a very important factor in using water soluble oils, it has a great effect on following items:

- Oil life

- Tool life

- Roughness of finished surface

- Effectiveness of filtering

- Foaming

- Rust and decomposition.

So, complete checking of the quality of the industrial water is necessary, we should use suitable industrial water for water soluble oils. If hard water is used for dilution, a portion of water soluble oil does not dissolve properly and it remains in a gum state, which adhere on the machines and its parts. So, it lowers the efficiency of oil and causes rust on the machines and work pieces. Chlorides and sulfides in water are the main reason for rust and corrosion.

Selection of cutting oil The cutting oil is usually selected, by considering the oil characteristics like lubricity, anti-stickiness and restricted conditions like working method and raw materials of work pieces. Neat oil or water soluble type is usually selected based on lubricity and anti stickiness, considering the working method and raw materials, the oil is decided. After selecting an oil, it is checked for primary and secondary effects, when some problems are noticed, some other type of oils has to be selected.