Schedule a Call Back

Corrugated Hoses

Corrugated Hoses

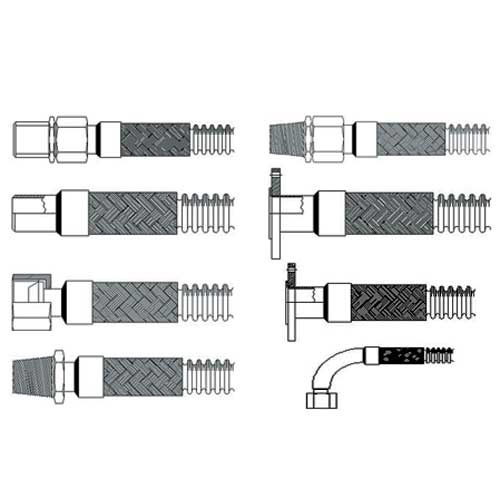

KPC Flexi Tubes, an ISO 9000: 2000 certified company, manufactures Corrugated Hoses that are specially developed with precision and utmost reliability and rigorously tested to meet all requirements and demands such as pressure, temperature, media, flexing requirements and environment. Construction: these corrugated hoses are manufactured by longitudinally welding strips to obtain thin wall tubes, which are then hydraulically corrugated by means of special tools. The combination of flexibility and pressure resistance is achieved by a row of annular corrugations each of which is capable of elastic deformation. Wire braiding: to increase pressure resistance and to provide protection against mechanical damage where necessary, corrugated metal hoses are provided with a single or double wire braiding. Testing: 100% testing on all hose assemblies are rigorously carried out prior to dispatch to meet KPC Flexi Tubes quality standards. Burst pressure testing and leak testing procedures are carried out to ensure joint integrity of hose-to-end fitting connections. End fittings: flexible metallic hose assemblies are obtained by attaching end fittings to corrugated hoses by either tag welding or silver brazing. These custom designed hose assemblies are then capable of being attached to the pipe work system. Fixed male or female connectors or swivel (male unions are normally provided up to 2" NB and fixed or swivel flanges over 2" NB. These are available in both stainless steel and carbon steel dependent upon the media. The company, established in 1990, is an associate of Micro Precision Products Pvt Ltd, and manufactures and exports high quality flexible metal tubes in two main formats: strip wound hoses and corrugated hoses.