Schedule a Call Back

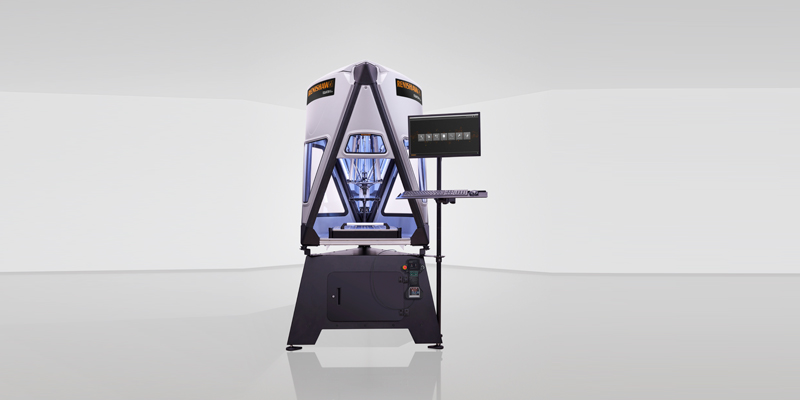

Coordinate Measuring Machines - 3D

Coordinate Measuring Machines - 3D

The Coordinate Measuring Machines are the ideal measurement systems for small-to-medium sized general mechanic and prismatic components. A wide variety of accessories that are state-of-the-art and suited for all dimensional inspection tasks are available. All GMT 3D CMM's are designed and manufactured with proven technology and come fitted with air bearings to ensure accuracy, reliability and repeatability. The structure of the machine has been designed such that it accurate to less than 5 microns. Computer aided accuracy and upgradation to direct computer controlled (DCC) are possible.

Product & Technology News

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||