Schedule a Call Back

Component Levelling Machines

Component Levelling Machines

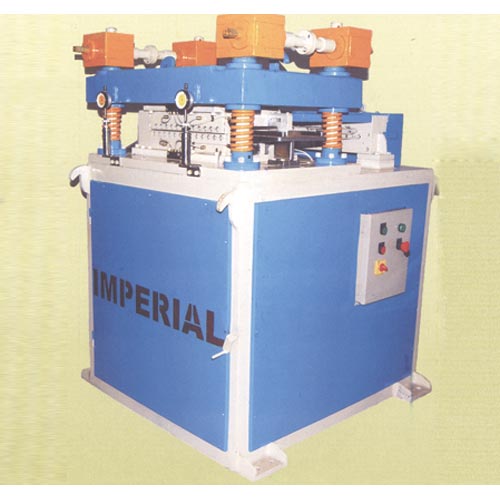

Imperial products, an iso 9001: 2000 certified company, manufactures component levelling machines for sheet metal components of any shape and profile being laser cut, plasma cut, stamped or blanked. These machines are used for levelling of components with minimum thickness of 0.1 mm and max thickness of 50 mm; width of the components can be from 10 mm to 2000 mm; max flatness accuracy of 0.030 mm have been achieved in some components; these machine are manufactured in 4Hi or 6Hi design (4Hi stands for single backup rolls and 6Hi stands for double backup rolls) as per component; and all the rollers are made from high grade alloy steel and are individually driver by propeller shafts; roller's setting can be done manually, motorized or hydraulic with PLC controller as per requirement of the customer. These machines are manufactured as per the customer requirements only. The company is engaged in manufacturing hi-power and precision engineered machines, using latest engineering drawing software to optimise the output of each and every machinery. With a vast experience of more than 26 years, all machines are engineered from premium quality raw materials. All machines are well heat-treated as well as meticulously machined up to required precision. Apart from maintaining quality, the company also ensures prompt deliveries. The company also Component Straightener (CE-MARK), Component Straightener, Cold Roll Forming Lines, Wire Straightening cum Cutting Machine, Roll Bending Machine, etc.