Schedule a Call Back

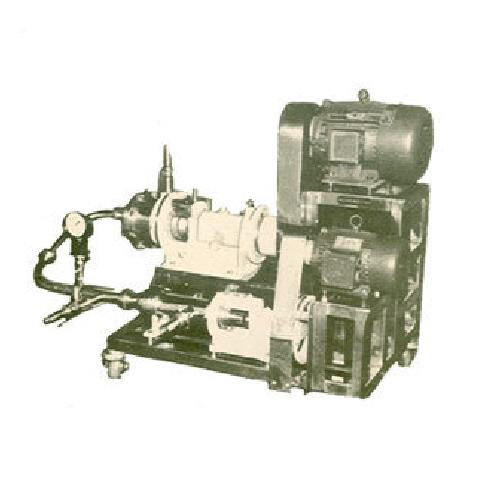

Colloid Mill

Colloid Mill

Chemech design of Inline Colloid Mills is suitable for continuous operation of ultimate dispersion with particle size reduction of pharmaceutical formulations, creams and cosmetics, ointments, food products etc., and the work is earned out in single pass under a closed and pressurized system with improved colour, reactivity and with no contamination. The Construction of the Mill is in stainless steel built, in jacket for heating or cooling serrated rotor and stator design with calibrated hardwheel adjustment with micrometer indicator for precisely varying the grinding gap between rotor and stator during the milling operation.

Chemech Engineering backed by the two decades of technical excellence and experience in the process industries has the answer for getting difficult solid-liquid and liquid-liquid product mix intimately. The capacity of the Colloid Mill manufactured by the company is ranging from 50 lit/hr - 7500 lit/hr.

Product & Technology News

- Inline horizontal design

- Works under closed and pressurised system

- Process is carried out in single pass under hydraulic shear

- Produces particle size upto 10-20-30 micron

- Discharges at elevated level

- Temperature rise is minimum and no aeration

- Quality uniform through out the batch

- Can handle high viscosity media

- Improves colour, reactivity with no contamination

- Jacketted mill housing for heating / cooling

- Simple to use, easy to clean, less expensive to maintain