Schedule a Call Back

Cage Vents

Cage Vents

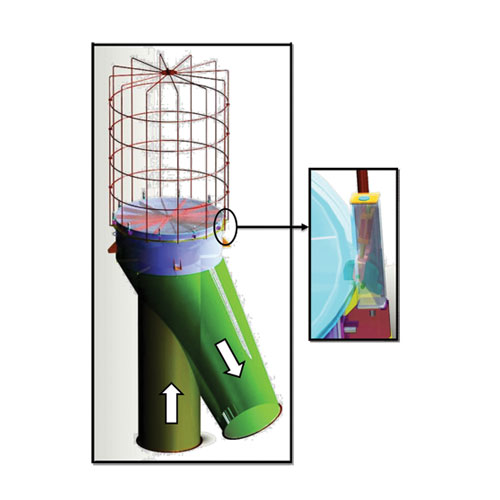

Air Control Engineering Pvt Ltd designs and manufactures Cage Vents. Coal grinding and various storage systems should be essentially protected against explosions and their highly hazardous consequences. Protection can theoretically be made by safe process conditions, viz., low oxygen content of the process air or purging inert gas like nitrogen and by installing safety techniques like explosion venting or cage vent, in company parlance. This technique is common and feasible in cement industry. Explosions occur only when three situations take place simultaneously – fuel, oxygen and an ignition source must appear together. If an inflammable finely ground material especially its dust are dispersed in air with sufficient oxygen static electricity or mechanically created sparks can originate an explosion with the attendant increase in pressure in process enclosures like grinders, silos, dust receptacles, etc. Coal dusts can build up sufficient heat to form a source of ignition. In cement industry, the standard procedure for protection against the consequential fall out of explosions is explosion venting through cage vent. Dust explosion is nothing but a steep pressure rise owing to air expansion as the consequence of heat. The nature of dust, predominantly its particle size distribution and burning properties, determine the maximum pressure, which will be reached in the enclosure in which the explosion occurs.