Schedule a Call Back

Bar Peeeling on Lathe

Bar Peeeling on Lathe

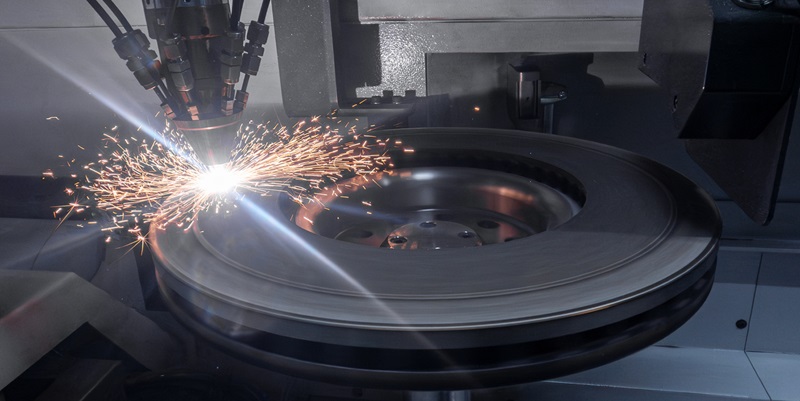

Innovations Unlimited offers innovation in Bar Peeeling on Lathe. This method of centreless peeling of long bars is a new innovation. Length of bar is no restriction. Specially designed core cutters are to be fitted in a 3-jaw chuck on the lathe headstock. The core cutter has 6 cutting tips. The saddle tool post holds another 3-jaw true chuck, with quick opening and closing system. The core cutter is rotated and the bar is fed through the lathe gearing to the saddle drive. Speeds and feeds can be adjusted as required, for the material to be peeled. The front end of the bar is reduced by pointing and fed into the core cutter, which has a specified inside diameter as required. Bars from 10 mm to 50 mm in mild steel, alloy steel and stainless steel can be peeled, to remove any surface defects. Depth of cut is up to 4 mm. Peeled bars can be then ground on centreless grinders to desired sizes if required. Reconditioned centreless grinders are offered at low prices. Special core cutters in HSS and carbide are offered. Regrinding of the core cutters done on special imported Swiss machine, as a special profile is desired.