Schedule a Call Back

Ball Mills

Ball Mills

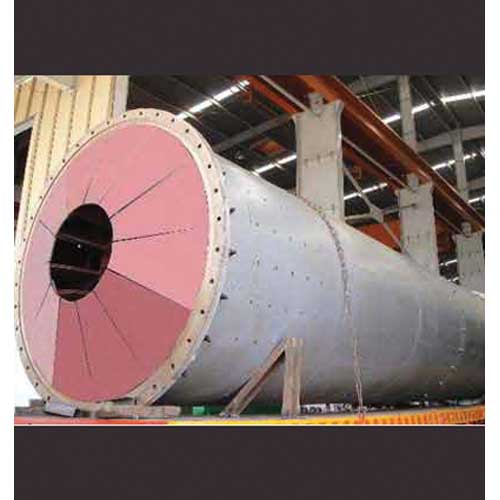

Ashoka Machine Tools Corporation offers Ball Mills. Ball mills are horizontal cylindrical shaped equipment that finds application in grinding hard minerals to the form of fine powder. The grinding operation is achieved here through rotation of cylinder with steel grinding balls/ceramic balls that causes balls to fall back into cylinder and onto material, which requires being grinded. These mills are divided into multiple chambers along its length with the chambers further divided by diaphragms. Design features: horizontal cylinder of ball mill fabricated using mild steel plates and rotated using side drive system present at one end of mill; drive comprises girth gear made from alloy steel casting that are bolted onto mill and driven by its pinion made of alloy steel forging through use of gear reducer and motor (coupled together); two ends of cylinder covered with mill ends (also known as mill headers) with one placed at each end - at inlet and at discharge; mill ends made out of alloy steel casting come with central inlet and discharge opening that is used as material entrance and exit point; mill headers coming rested on fabricated trunnions at both ends on which headers rotate on special self lubricating white metal lining; option of external lubrication system provided for keeping mill headers optimally lubricated at all times; can be provided with other accessories like set of low pressure and high pressure pumps that support pre-jacking mills during start-up; grinding media is generally made of high-chromium steel/ manganese steel; and mill liners are clad throughout its periphery of length and are made of high chromium steel/manganese steel.